My spot welder with tungsten electrodes is driven with DC from a bank of ultracapacitors.

“Continue reading” for animations and photos of the spot welder in action.

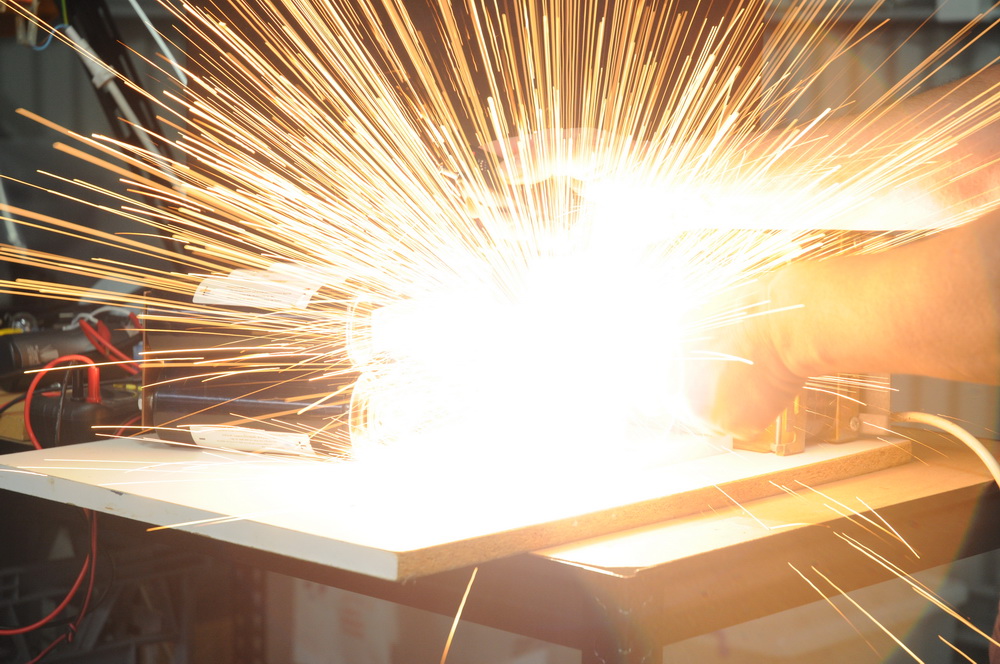

I am juggling the camera remote, the swing arm and the work piece.

Approved by Occupational Health and Safety for hand protection.

Tech details: (6 x 2.6 kF (kilo not micro), 2.5 V rated 600 A. This gives nominal 15 V 600 A peak to a total of about 40 kJ. Running a bit less (14 V) due to 5 % uneven load sharing with cap tolerances. All delivered in a few seconds.

Does it work as a spot welder? Not as it stands due to too much power and no way to regulate it. And there is no switch to allow you to get the work into place before firing.

On the other hand, the transformer in the background is the basis for the AC spot welder. This will put out 800 A short circuit but can be controlled with a variac to be more finely controlled and consistent. Switching the mains is easier than switching the Ultracaps output.

I guess if you were making many consistent welds in a production line you set your total energy to optimum and the ultracaps would be fine. That would only require a small power supply rather than a big transformer and variac.

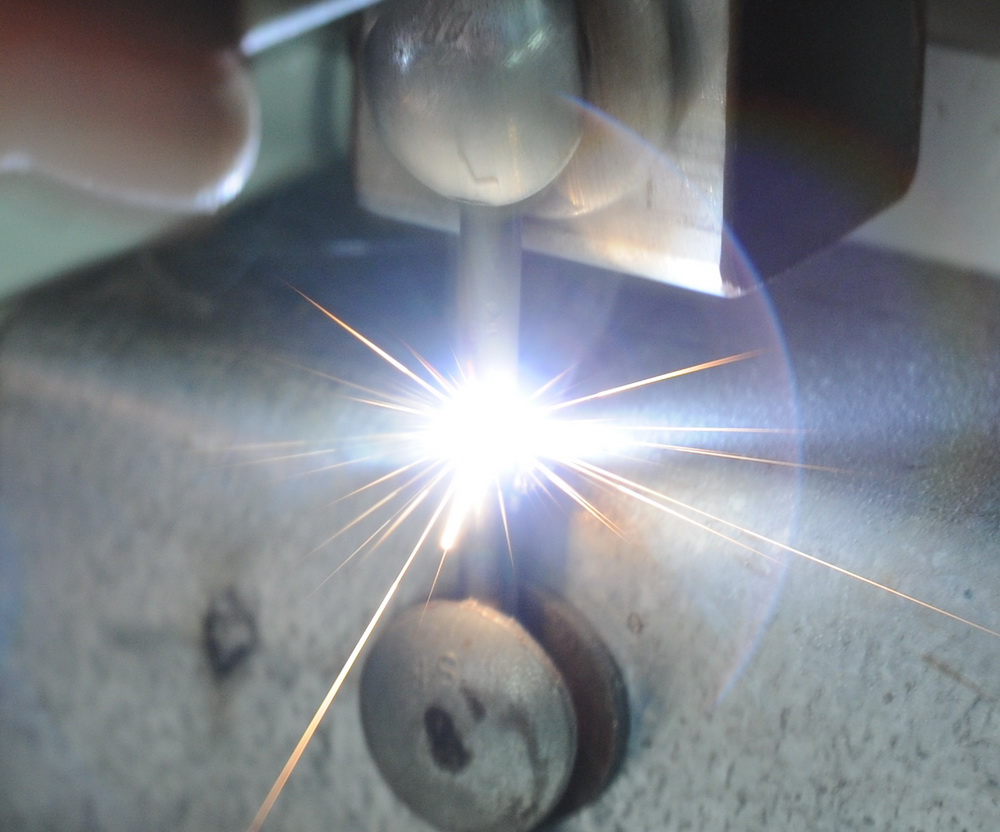

A loose bolt on one of the ultracaps causes sparks and a close view of the tungsten rods.

Tungsten electrodes become welded together and drain the ultracaps.

Related pages

AC spot welder The AC version provides 800 A but has fine control

Ultracapacitors The main article on these big capacitors

Marinov Motor Another high current device

Low voltage but high current Make your own high current supply

Pulse power Electrical explosive effects with high voltage

Try something else

Sparkler effects Similar sparkles, different method

Railgun 2 making a simple railgun.

External links

Resistance Spot Welding Wiki

Google+ post (mine) on ultracapacitor related spot welding

Photo Date: May 19, 2012