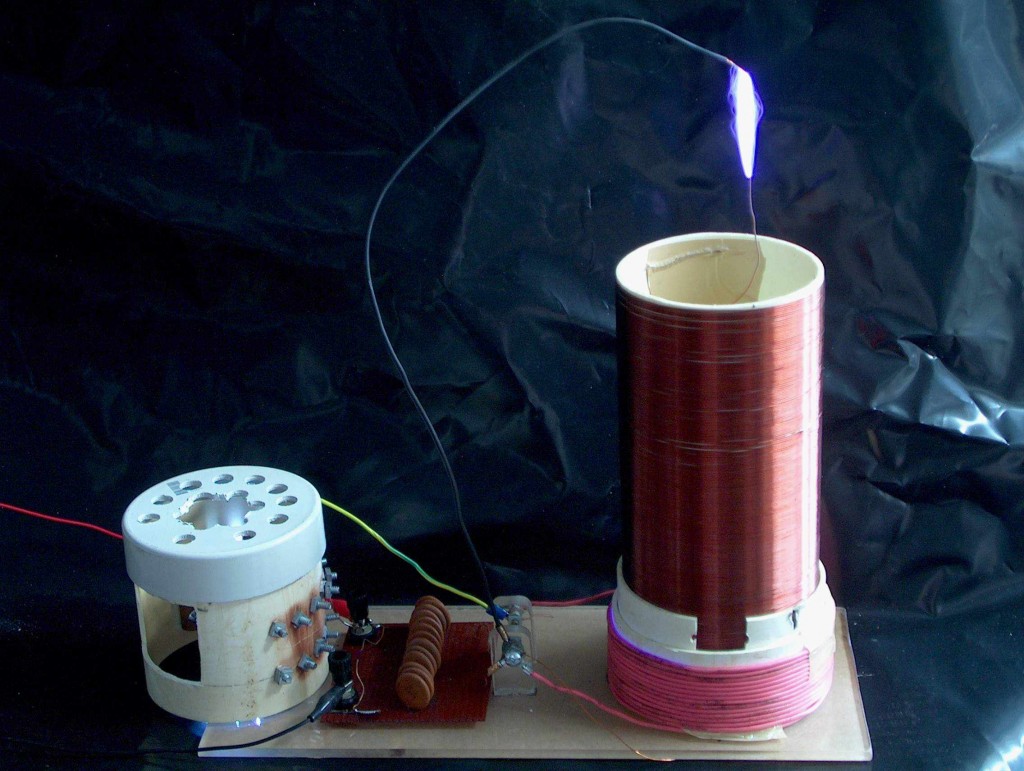

This is a mini Tesla coil, made from odd parts from other projects and a neon sign transformer that runs from 240 V mains.

“Continue reading” for more details and photos.

The photo above is from the Uni of WA Expo in 2007 and features Oscar showing his best light sabre effect.

Two inch sparks onto my hand. There is some motion artefact with my hand but not the equipment or sparks. This is done with a clear knowledge of earth paths and at very low power levels on a small coil with no toroid capacitance. Wetting my hand beforehand reduces the sensation to a mild prickle. This should not be attempted on a large coil regardless of power input.

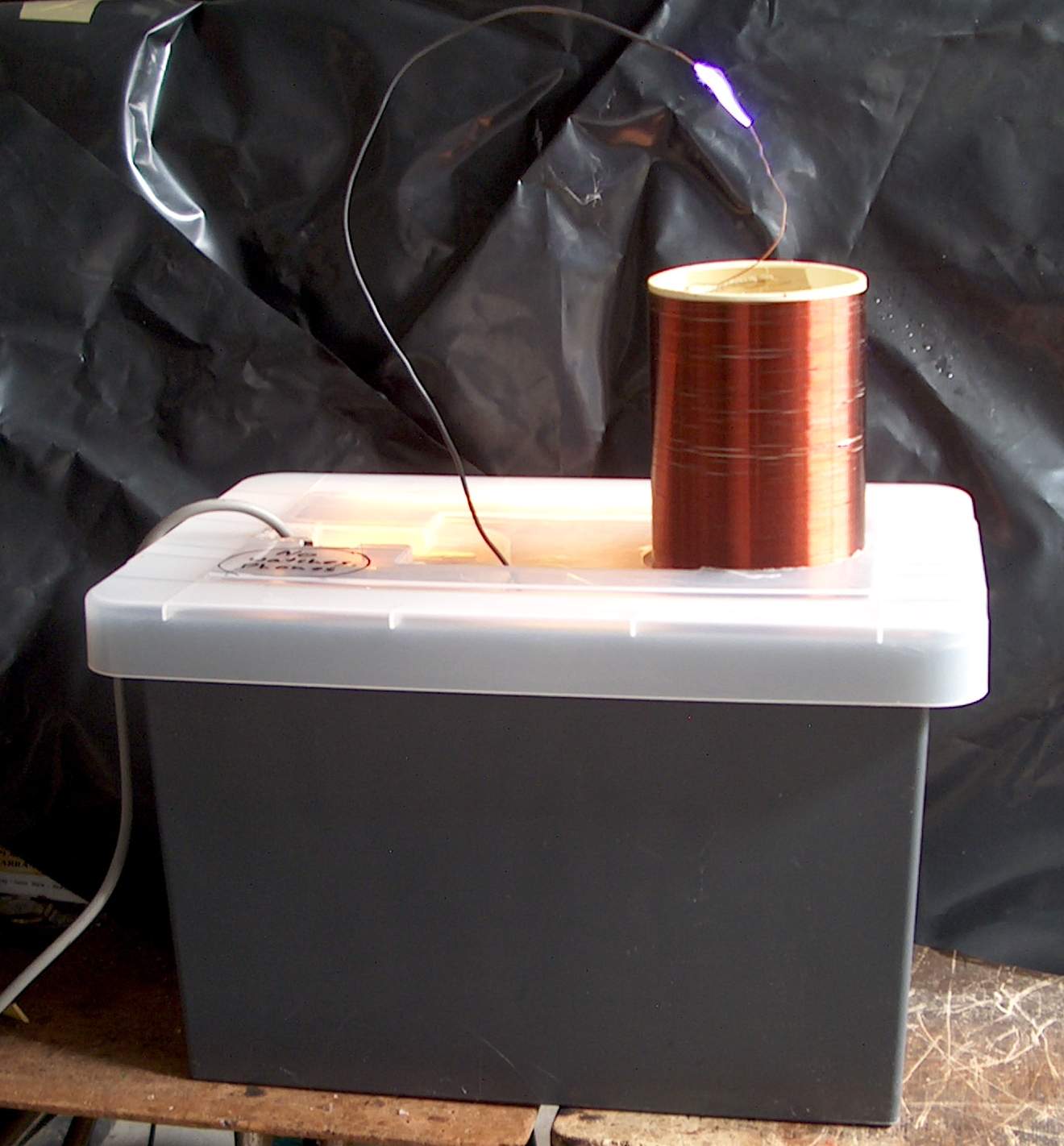

This little coil has been popular way beyond the effort to make it. It has now been on Australian TV on 3 occasions and on TV in 15 countries (e.g. US, UK, China, Holland, Norway, Switzerland, Denmark, Turkey and others). Now on loan to the Uni of Western Australia Physics Dept. where it gets pulled out for off site demonstrations.

Here are some technical details. This is a small Tesla coil running on half of a neon sign transformer (NST) giving 6 kV at 30 mA. The other half of the NST had been burnt out and increased the current draw mildly. The Tesla coil components include a high voltage source (the NST) which charges a capacitor (the row of coin sized light brown objects below the green wire). This then discharges through the spark gap (white tube on left with perforated cap) and passes though the primary coil (pink wire). This sudden high current induces a much larger voltage in the many turns of the secondary (brown copper coil).

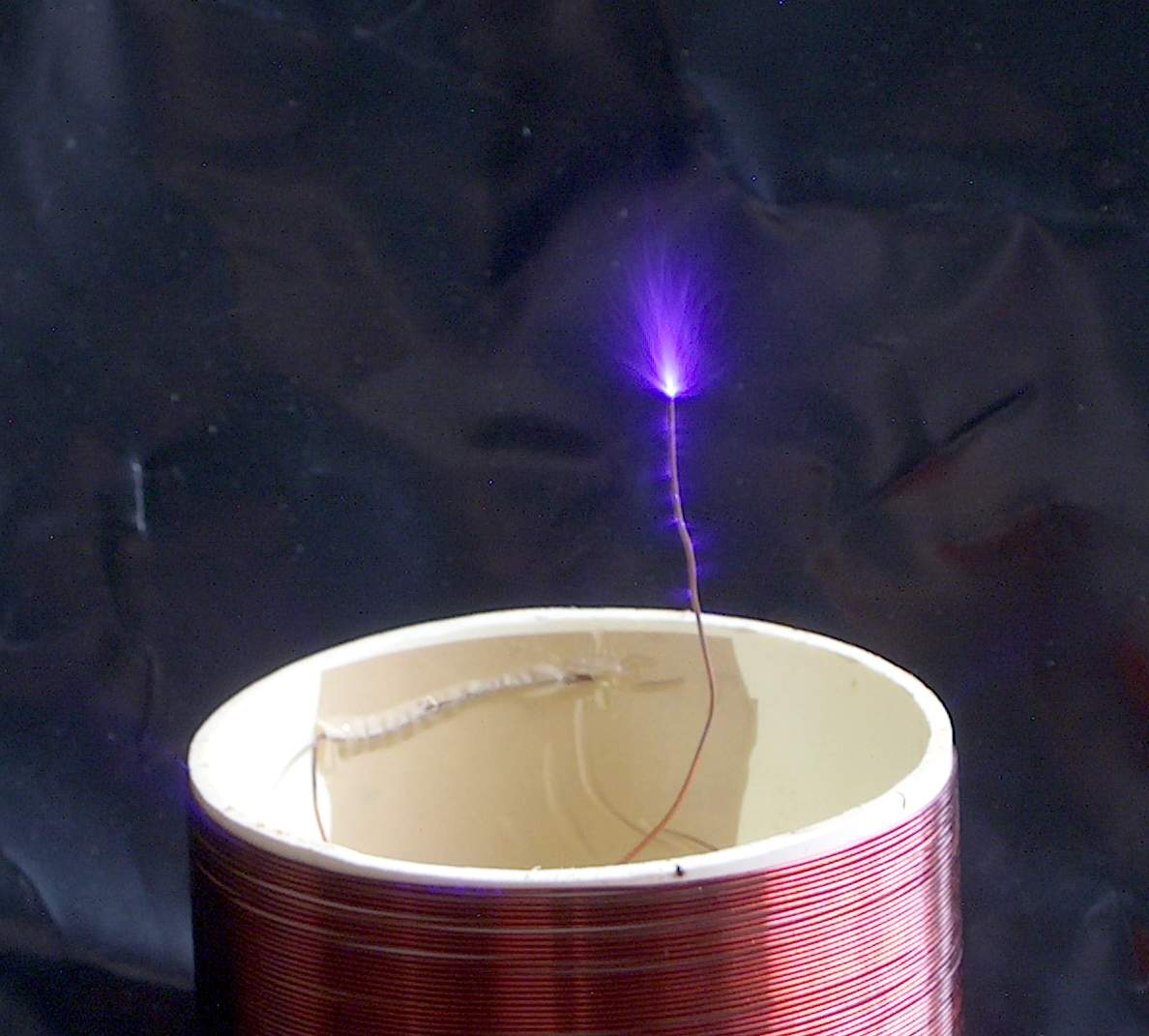

Corona from sharp points connected to high voltage.

Corona from sharp points connected to high voltage.

The spark gap above uses 3 segments of an 11 segment gap (as used by the TCBOR and Richard Quick) with 1/2 inch pipe close but not touching. This was a hand me down from a larger coil. If made specifically for this coil then 4 or 5 copper pipes could have been bolted on to a flat section of acrylic or other insulator as the geometry of the cylindrical set-up is trickier. The primary is a cylindrical 15 turns of PVC coated wire and the secondary is about 11 inches with 260 turns of 20 G (0.031 inch = 0.81 mm) enamelled wire on a 4 inch PVC pipe. The spacing between primary and secondary is also from the same 4 inch PVC with two sections cut longitudinally to allow them to snap on to the secondary. The capacitor is a series connection of 13 x 100 nF 2.5 kV ceramics giving 7.7 nF at a nominal 32 kV. There is no toroid and the secondary earth goes to the NST and mains earth. This is about as quick, easy and safe as they come for 2 inch sparks.

Above, for kids of all ages. I probably run this coil more for demo’s than any other as it is quick, easy and safe. Charge up your light sabre here.

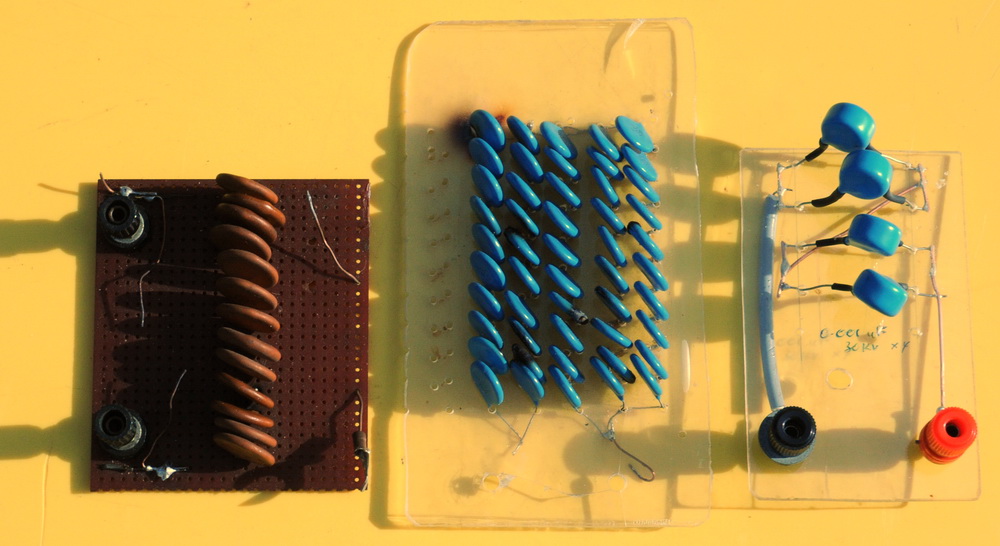

Above, for 2009, I have changed the caps again. The originals are shown on the left (one string of 13 x 10 nF @ 2.5 kV = 0.77 nF 32 kV) which lasted 20 years and have a couple of failures. The centre caps were the disastrous ones which fail after only minutes (Five strings of 10 x 10 nF @ 3 kV = 5 nF 30 kV). The new ones are on the right (2 strings of 2 x 1 nF @ 30 kV = 1 nF 60 kV) seem to work so far. I have also removed windings back to 10 turns on the primary to improve spark length to 2.5 inches (6 cm).

Above, for 2009, I have changed the caps again. The originals are shown on the left (one string of 13 x 10 nF @ 2.5 kV = 0.77 nF 32 kV) which lasted 20 years and have a couple of failures. The centre caps were the disastrous ones which fail after only minutes (Five strings of 10 x 10 nF @ 3 kV = 5 nF 30 kV). The new ones are on the right (2 strings of 2 x 1 nF @ 30 kV = 1 nF 60 kV) seem to work so far. I have also removed windings back to 10 turns on the primary to improve spark length to 2.5 inches (6 cm).

I have also removed windings back to 10 turns on the primary to improve spark length to 2.5 inches (6 cm). Also changed the set-up to have the spark gap across the transformer secondary which gives it better protection. I have added some mains filtering and an aluminium sheet counterpoise at the base.

Related pages

Try something else

External links

Photo Dates: 2004, 2009

Briefcase Tesla coil

Briefcase Tesla coil Burning steel wool on my hand

Burning steel wool on my hand