This project describes building two identical Tesla coils and driving them with a solid state driver. “Continue reading” for more details and photos.

This project describes building two identical Tesla coils and driving them with a solid state driver. “Continue reading” for more details and photos.

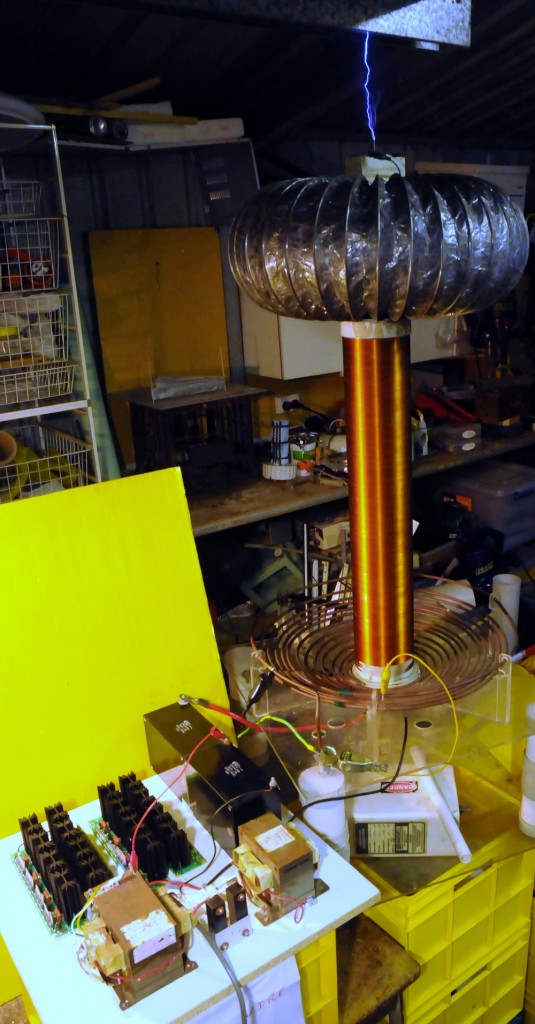

The twin coils firing above with about 80 cm spark from two 50 cm secondary coils. This is only running on about 60 – 70 % of full voltage due to a problem with some of the SISG modules.

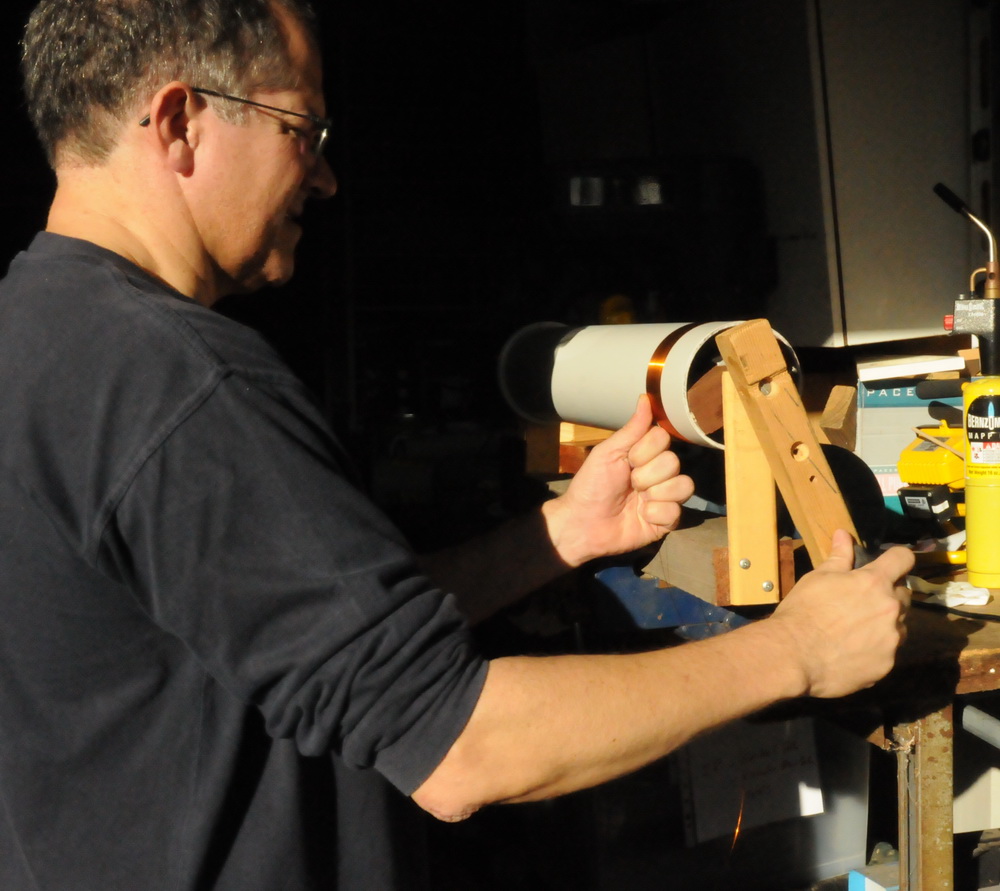

Above shows the winding of the 1260 turns on each secondary using thumb guidance and a manual winder.

Above shows the winding of the 1260 turns on each secondary using thumb guidance and a manual winder.

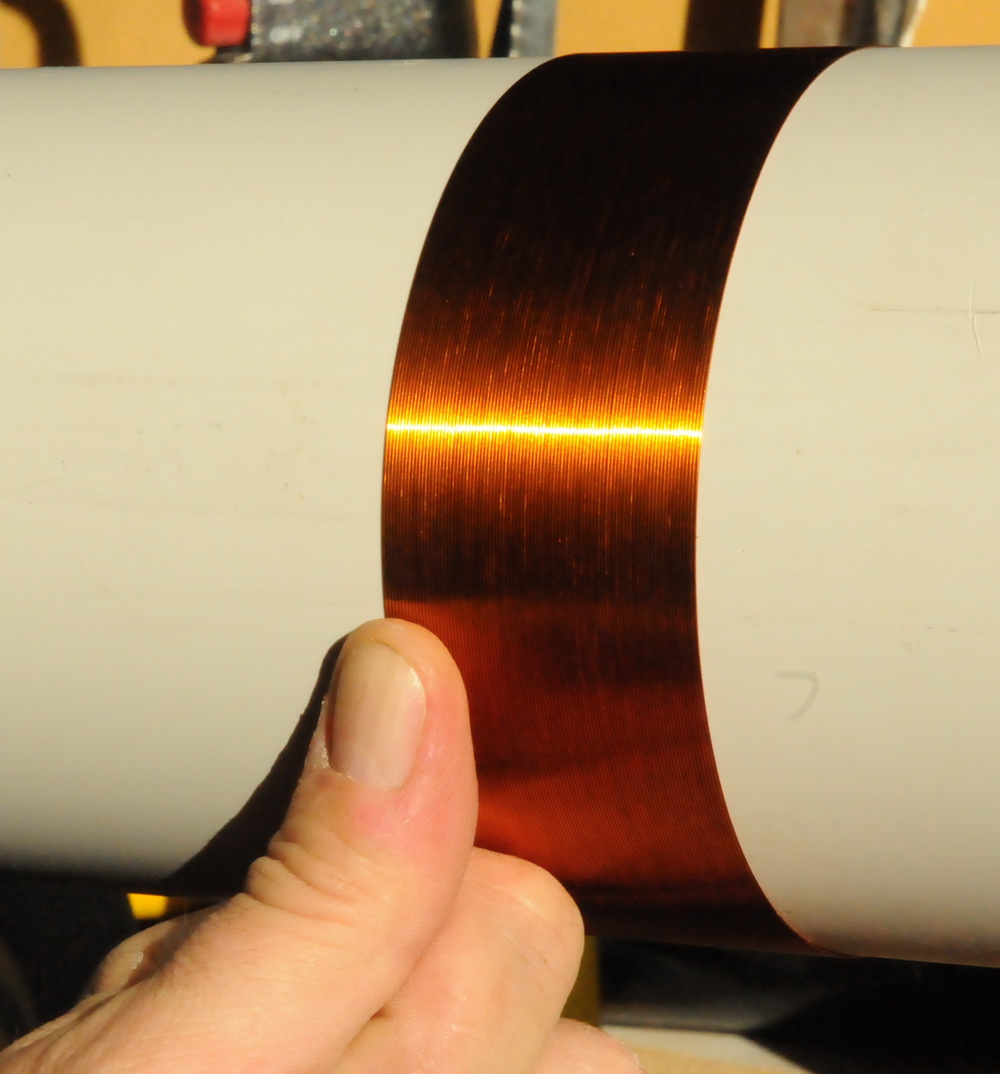

Then it gets a couple of coats of polyurethane (common timber floor sealant). Specs; 1260 turns 26 G 0.40 mm (.016 inches) over 50.5 cm on 11 cm diam 57.8 cm length 3.5 mm thick PVC (between 5.0 cm to 57.5 cm.

Then it gets a couple of coats of polyurethane (common timber floor sealant). Specs; 1260 turns 26 G 0.40 mm (.016 inches) over 50.5 cm on 11 cm diam 57.8 cm length 3.5 mm thick PVC (between 5.0 cm to 57.5 cm.

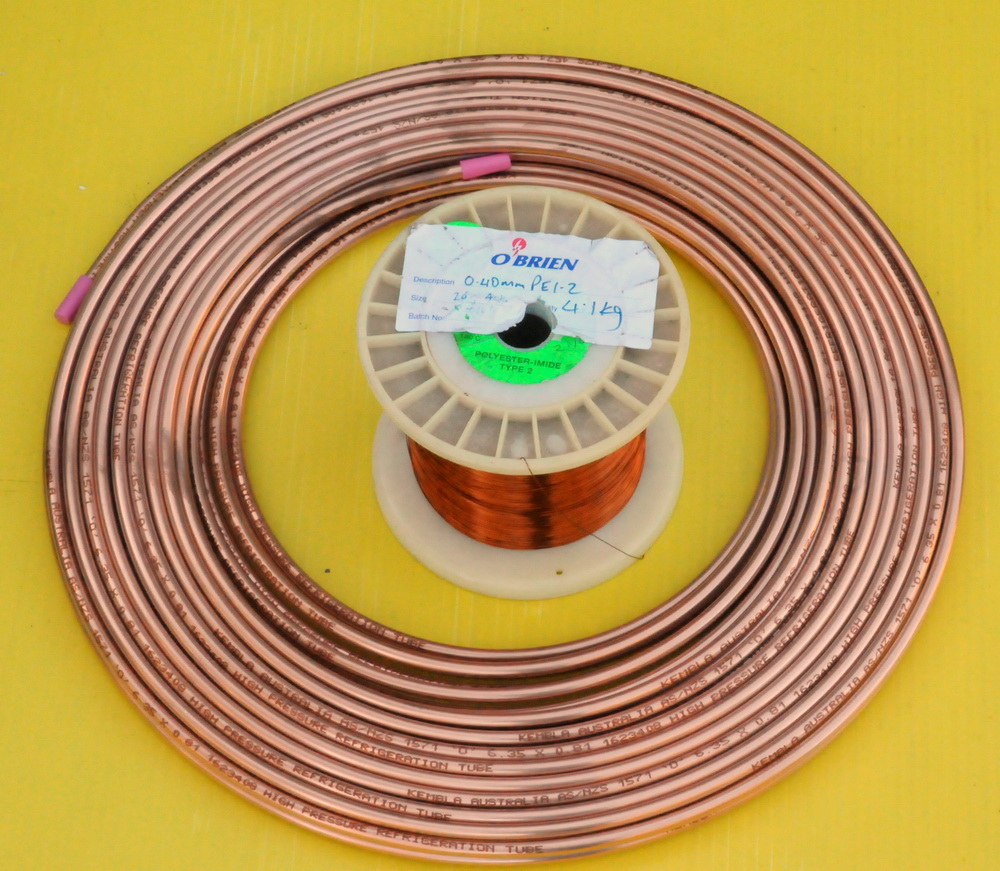

Above shows the 1/4 inch refrigeration tubing used to make the primary and the fine polyimide coated high temperature magnet wire for the secondary.

Above shows the 1/4 inch refrigeration tubing used to make the primary and the fine polyimide coated high temperature magnet wire for the secondary.  Above shows the temporary 8 inch plastic float is coated with aluminum foil and is assembled with some PVC connection and screws on the end of the secondary. I am trying to keep this relatively easy to dismantle for travel and repairs.

Above shows the temporary 8 inch plastic float is coated with aluminum foil and is assembled with some PVC connection and screws on the end of the secondary. I am trying to keep this relatively easy to dismantle for travel and repairs.

The primary coil above is unconventional as I am using a cylindrical coil rather than a flat helical one. It was wound in minutes, is easily spaced and tapping is with fuse holders and heavy flexible multi strand wire. I can tap both ends. Once I get the best results by adjusting the number of turns, I then go up or down with the same number of turns. This adjusts the coupling to further optimize the spark length. I must admit this is a lot more adjustable, faster to wind and more compact than a helical coil. Most spark gap coils use a helical primary and most DRSSTC solid state coils use a cylindrical one as they work better with higher coupling. I am using copper pipe as a coax line to get the power from the tank caps to minimise losses.

The primary coil above is unconventional as I am using a cylindrical coil rather than a flat helical one. It was wound in minutes, is easily spaced and tapping is with fuse holders and heavy flexible multi strand wire. I can tap both ends. Once I get the best results by adjusting the number of turns, I then go up or down with the same number of turns. This adjusts the coupling to further optimize the spark length. I must admit this is a lot more adjustable, faster to wind and more compact than a helical coil. Most spark gap coils use a helical primary and most DRSSTC solid state coils use a cylindrical one as they work better with higher coupling. I am using copper pipe as a coax line to get the power from the tank caps to minimise losses.

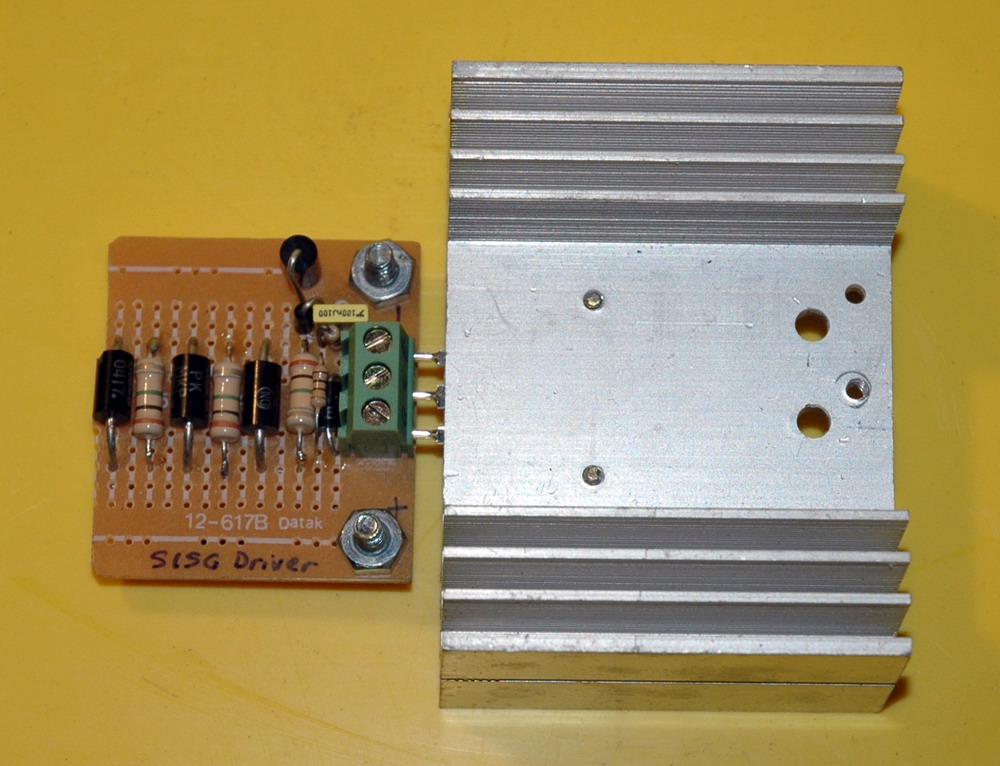

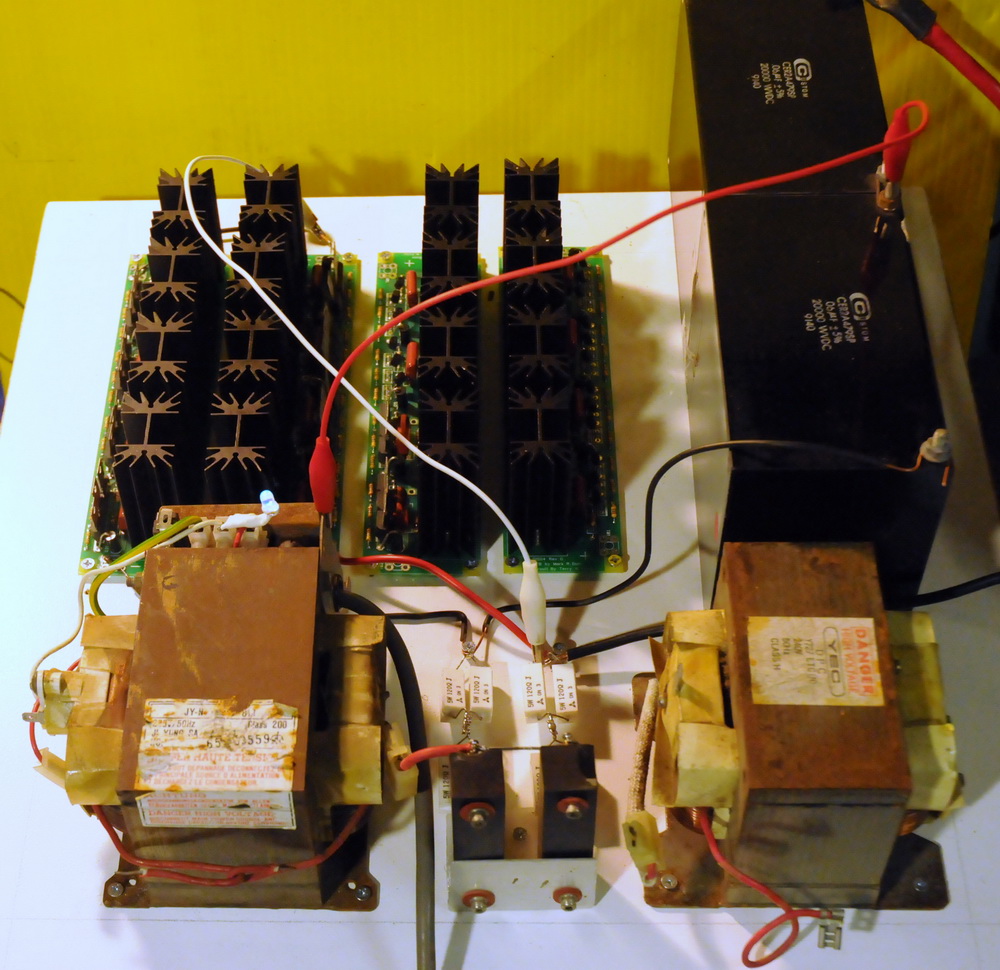

Above shows the SISG supply driver boards where each 900V section has its own IGBT with heat sink triggered by 3 x 300 V SIDAC’s. Total of 4 boards with 4 sections giving 14.4 kV firing voltage. The supply is from two MOT’s in a clever voltage multiplier arrangement where the tank cap doubles as the multipliers caps to generate over 12 kV.

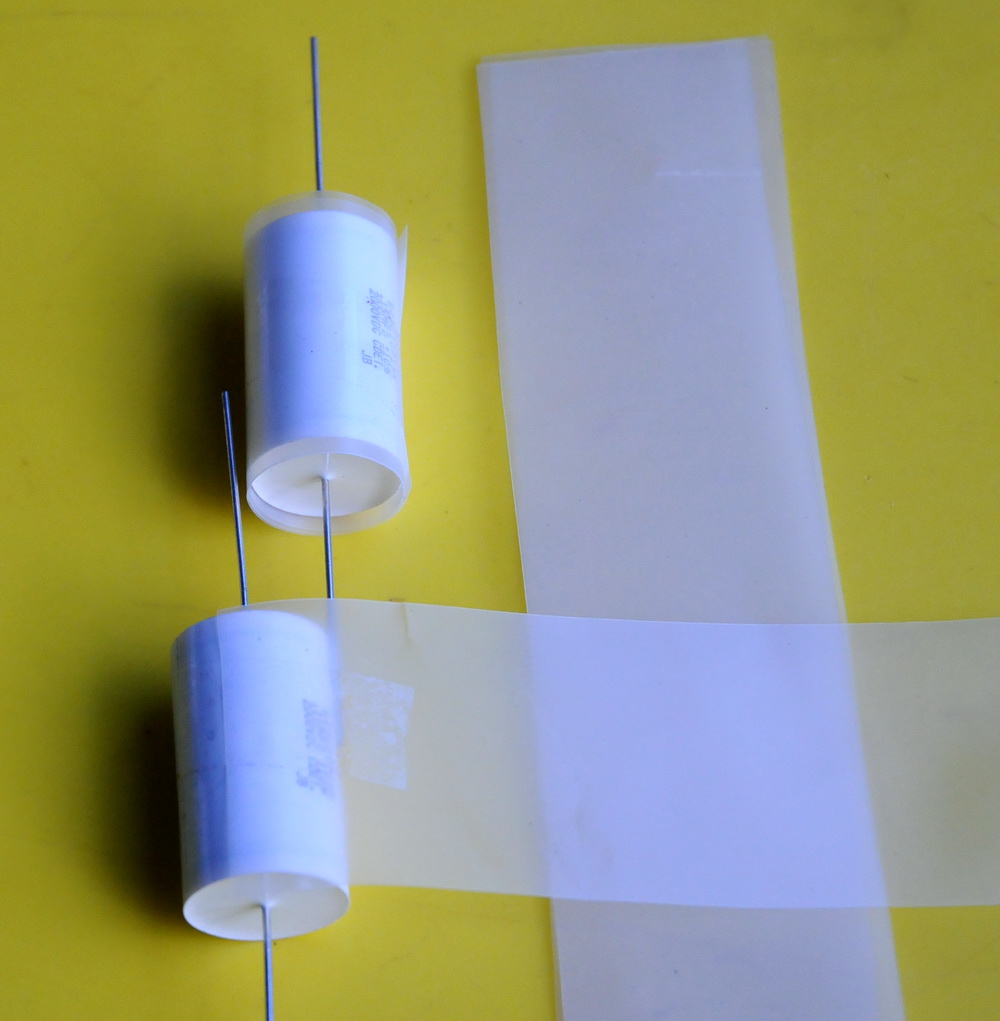

Above shows the 80 capacitors in 8 strings of 10. The capacitors for this voltage multiplier set up need to be center tapped. As I am not expecting a significant temperature rise and needed them to be very compact I individually wrapped 3 layers of polyethylene around each of the 80 caps so they could be touching and still stand off a maximum of 4kV between them. So far so good. I am only using 60 caps at present. I am not using resistors across each cap or even across the whole bank as the voltage in circuit decays in about 5 seconds.

Above shows the 80 capacitors in 8 strings of 10. The capacitors for this voltage multiplier set up need to be center tapped. As I am not expecting a significant temperature rise and needed them to be very compact I individually wrapped 3 layers of polyethylene around each of the 80 caps so they could be touching and still stand off a maximum of 4kV between them. So far so good. I am only using 60 caps at present. I am not using resistors across each cap or even across the whole bank as the voltage in circuit decays in about 5 seconds.

Above shows initial low power runs with a puny 1 cm spark. After tuning and boosting power the output rose to sparks up to 60 cm from a single 50 cm coil.

Above shows initial low power runs with a puny 1 cm spark. After tuning and boosting power the output rose to sparks up to 60 cm from a single 50 cm coil.

Above are the twins in action. Currently giving about 100 cm sparks between the coils. Still not fully optimized and hope for more. Sparks are purplish rather than bright white due to the relatively low capacitance of the spherical topload.

Above are the twins in action. Currently giving about 100 cm sparks between the coils. Still not fully optimized and hope for more. Sparks are purplish rather than bright white due to the relatively low capacitance of the spherical topload.

One thing I did not realise is a note from Terry Fritz’s document.

” You have to be careful to turn up the variac until is just starts to run smoothly (120 BPS) and no more. If you turn up the voltage too high, the BPS rate can go up dramatically and

overheat the IGBTs. Higher BPS does not seem to increase spark length other than making

them sound funny. Sort of “screetchy”.”

Hence pushing above the starting level won’t help but will increase current drain. This system generates 30 inch sparks but would be better optimized with a lower resonant frequency and bigger toroid.

Related pages

Try something else

External links

SISG development Terry Fritz write up of the first single MOT SISG system.

http://drsstc.com/~sisg/files/BigSISGCoil/ Lots of SISG related files from Terry Fritz.

http://deanostoybox.com/hot-streamer/temp/PRIANHA-III-too-early.gif The circuit diagram of the 2 MOT Piranha system.

http://www.teslaboys.com/SISG/SISG4BOM.pdf Parts list for 1 board

http://www.classictesla.com/photos/sisg/sisg.html Bart Anderson’s SISG coil

Handheld twin coil at Makers Faire

Photo Date: Aug 1, 2009