The second version 4 inch diameter Tesla coil uses much higher power components.

For more details and photos:

Power is from 4 MOTs (microwave oven transformers) under oil with an angle grinder ARSG (asynchronous rotary spark gap) on a 4 x 23 inch coil using a polyethylene/oil capacitor in a 6 inch PVC for around 4 ft sparks.

The TC in daylight (above). The capacitor is the upright white cylinder, the yellow box is the ARSG, the brown upright is the secondary coil and the double toroid is on top.

![]()

Primary: 1/4 inch copper piping wound to 11 turns on acrylic supports. Tapped at around 4 turns for a 48 nF tank capacitor. This gets quite warm in action after only a few minutes, particularly the innermost turns.

![]()

Secondary:

648 turns of 19 G (0.81 mm = 0.0335 inch) enameled wire taking up 24 inches on 4 1/2 inch PVC pipe. The 10.5 turn/cm (27 turns/inch) gives a winding wire width of 0.851 mm (0.0345 inch) giving a 97% winding percentage . Coated with several coats of spray on polyurethane sealer. This retains a bit of a surface static charge after use and can give small sparks onto your hands near the top of the coil. I have had to remove 2 turns in three different places due to breakdowns after quite some use. They all occurred several inches from the base. The PVC former has acrylic end caps and one ventilation hole as I used PVC solvent based glues. (This is a no-no because of explosion risk. Non solvent based glues such as epoxy are preferred). I have used a PVC screw in base to allow dismantling. I’ve now wound a second identical coil as a spare prior to my school display as I was worried about further breakdowns. Measured resonant frequency is 297 kHz.

![]()

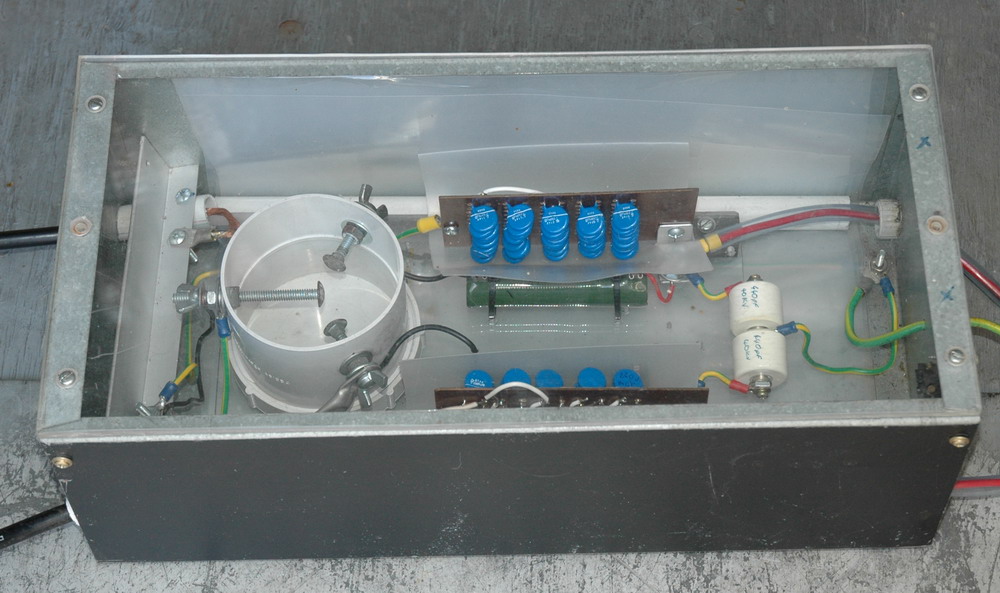

Tank capacitor “rolled poly”:

2002 The photo at the top of the page shows a 35 nF capacitor made from polyethylene and aluminium foil rolled and immersed in transformer oil. I didn’t vacuum seal these and the lid unscrews. They are 6 x 24 inches mounted vertically. They are mostly filled with low viscosity naphthenic transformer oil (A$70 for 20 liters) allows free bubbling out of air particularly in the rather loose z folding. I used a z folding approach hoping to minimize inductance (it probably doesn’t) and this has given the hottest sparks on this system. At these powers and with the very thin dielectric 4 mils x 4 this capacitor didn’t last too long. Other capacitors I have used were rolled not z folded and ranged from 15 to 48 nF with progressive increase in power and heat generation in all primary circuit wiring. The 1/2 inch steel bolts from the capacitor got hot enough after less than 1 minute with 48 nF to give me a significant burn. They probably had rather high RF hysteresis losses and have subsequently been replaced with brass ones which run much cooler.

Note that only one of these capacitors is still running after 2 years which is the 6 nF one in the right of the group photo above. It has been used up to almost 50 kV but not in Tesla coil duty.

Note that only one of these capacitors is still running after 2 years which is the 6 nF one in the right of the group photo above. It has been used up to almost 50 kV but not in Tesla coil duty.

My best and longest lived Tesla coil capacitor is 48 nF constructed with 2 in series internally with (as I recall) only 2 layers of 4 mils each. This has lasted longer than single capacitors with 10 layers of 4 mils each. The right photo shows the two separate capacitors wired internally.

![]()

Toroid

The double toroid is 6 inch air conditioning duct with the lower one being 15 inches and the upper 24 inches diameter. It has been a bit smoothed with aluminium tape. It is well behaved and I have not had any problems with top of secondary coil breakout.

![]()

Power supply

The power supply (below) is made of 4 MOT’s (microwave oven transformers) in transformer oil in a plastic container. This takes 250 V up to 8 kV. Not fancy but cheap. Each 2 kV secondary is in series and each 250 V primary is in parallel. There are a 20 A circuit breaker, 20 A key switch and an earth point mounted on an acrylic sheet which sits on an internal lip. There is also limited power factor correction capacitors (30 uF polypropylene but needs more) and microwave oven suppression circuitry. This has been most reliable. I was concerned about explosion risk if a spark occurred in the air space, however, this has occurred without any problem and the transformer oil seems to be of low volatility.

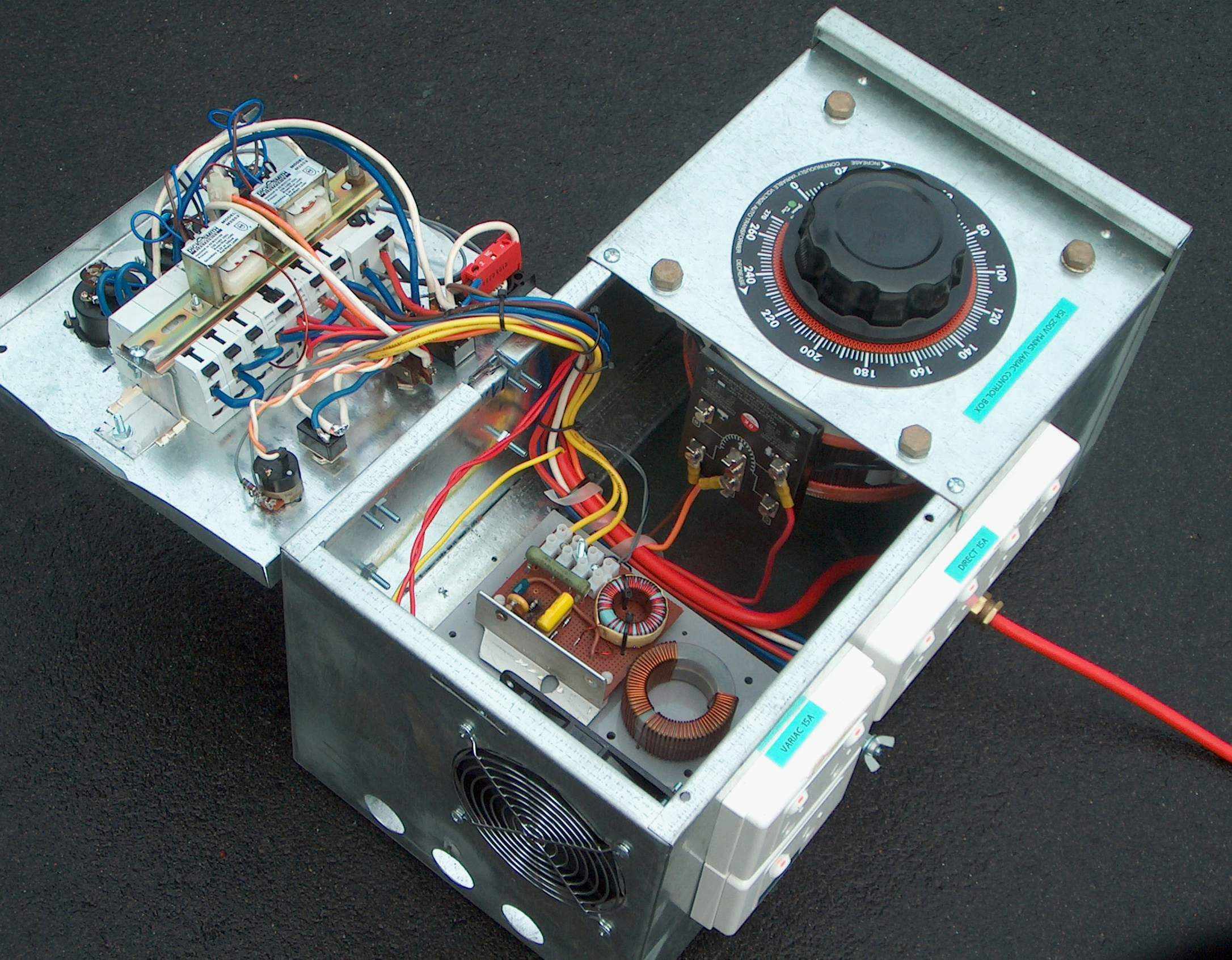

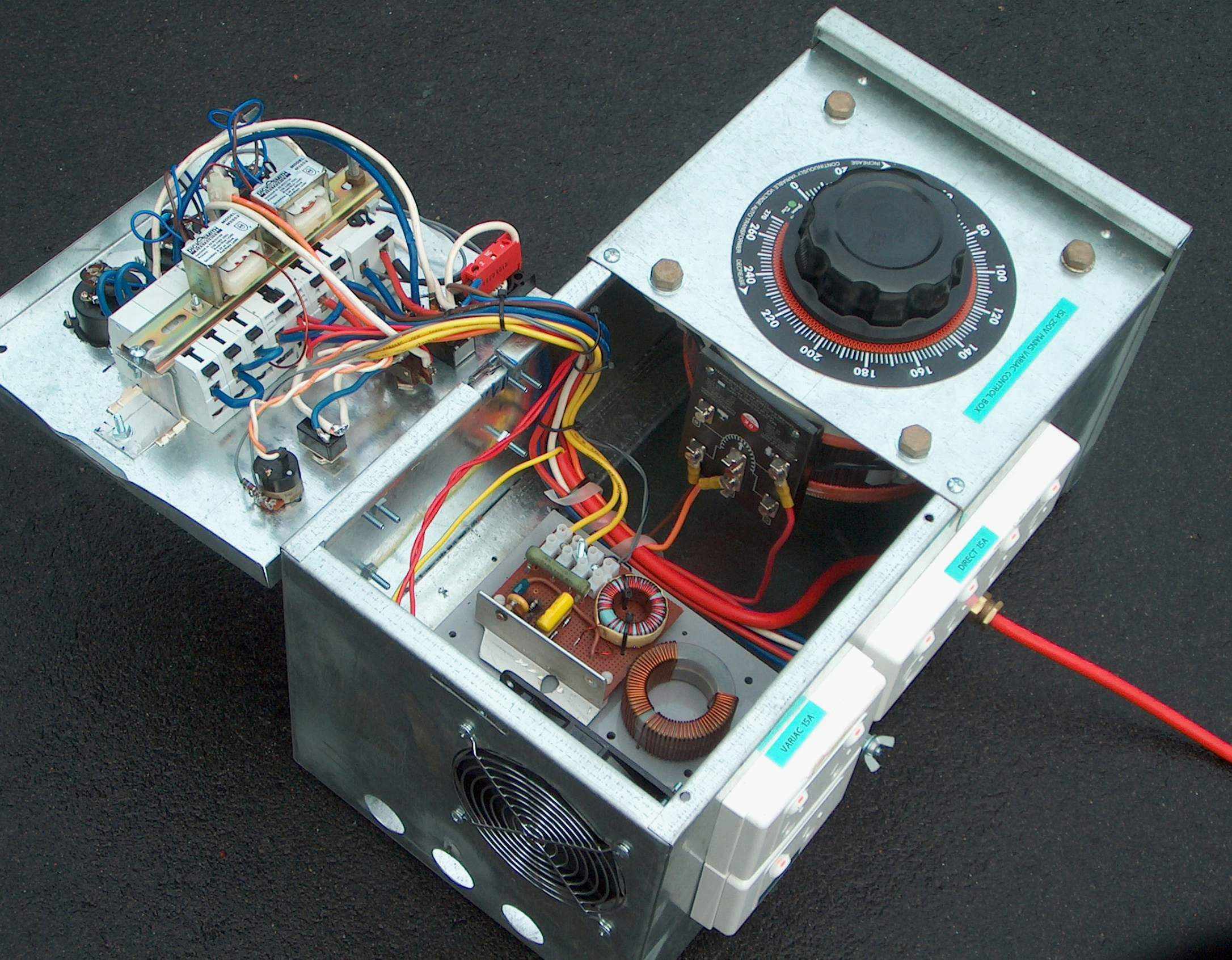

The variac control box

This is a variable transformer that varies AC voltage like a “volume control” for the mains. The variac control box (below) is fan cooled and the variac is rated at 15 A 240 V. I have run this at higher powers with no discernible heating. It is mounted in a galvanised iron domestic meter box. It has various cutouts including RCD’s (residual current devices) on the variac and direct circuits. There are meters for variac output voltage and current as well as total current. I also have included a series circuit which can switch in a ballast resistance (such as a fan heater), or inductance (such as a shorted MOT). The direct mains line has a triac controller for variable speed for my ARSG motor. I have blown this twice and have replaced this with a limiting inductor. Current draw with 32 nF tank capacitor is about 15 A 250 V in with the variac at about 180 V. It goes hard off scale at 20 A when on full although for short runs doesn’t trip the 20 A breakers. Current draw is higher with a total of 92 nF tank cap.

Filter circuit

The filter circuit is to prevent high voltages coming back to the main transformer. This is particularly important when using NST’s which are rather fragile with respect to overvoltage. It is inserted between the main transformer and the primary circuit (tank cap, spark gap and primary coil).

The left photo shows the old version with 2 ferrite core inductors shunted on the MOT side by a ceramic capacitor rated at 570 pF 40 kV. They recently arced over and blew an inch off the ends of the ferrite rods. There is a safety gap set to a rather wide 1 inch. If this fires there is a big flaming arc that doesn’t extinguish. All this is rather old fashioned and has been shown to be ineffective. The upgrade in the right photo uses a more sophisticated “Terry filter” with MOV’s (metal oxide varistors) resistors and capacitors and are far better at protecting neon sign transformers. The safety gap is set much closer and it is set so it just doesn’t fire when connected to the transformer alone. In operation there will be resonant voltage rise but also voltage drop under load so this seems to be the right level.

![]()

Spark gap

The spark gap (below) is an ARSG (asynchronous rotary spark gap) using a 500 W angle grinder of a nominal 11,000 RPM . This has been measured in the current setup at 9,000 RPM = 150 RPS which gives giving a fairly high 1200 bps (breaks per second). This is a lot higher than other ARSG’s that often run around 400 bps.

The disc is 1/2 in. thick made of Tufnol with 8 x 1/4 in. steel bolts. Tufnol is a high pressure laminate and has been used by others for this purpose. It is much stronger and temperature resistant than my previous polycarbonate wheels which were prone to cracking or creeping of the outer electrodes at highest power levels. The stationary electrodes are 3/16 inch 2% thoriated tungsten. The tungsten rods wear down and require adjusting perhaps every 15 – 30 mins of use. Cooling is with the angle grinder fan and when needed, I now use a garden leaf blower as well. This is not ideal as the blower motor (1100 W) is cooled by that airflow so it is actually delivering warm air although in large volumes. Added to the angle grinder 500 W and the spark gap ?500 – 1000 W gives over 2 kW that has to be air cooled. The ARSG is enclosed in a solid thick polypropylene box and the top is acrylic with large ventilation holes but is also protected by the Tesla coil acrylic base a few inches above it. I have some token shielding which is grounded but keep tripping my RCD’s when I get a strike to the ground rail.

The third photo above with the sparks was taken with 4 kV direct from the power supply giving a mild spark for ease of photography. In action with the capacitors running the Tesla coil it is blindingly bright.

Hi,

I’ve never seen this sort of arc over either, but looking at it purely from

a chemistry viewpoint, the dust is partially conductive. It is a rather

complex mix of four compounds + intermediates formed when tungsten is heated

in air. The resulting four primary oxidation products are:

Brown colored tungsten nitride which is conductive

Copper/bronze colored tungsten (IV) oxide, which is highly conductive

Yellow colored tungsten (VI) oxide, which is not conductive (used as a

yellow pigment, WO3)

Blue colored tungsten pentoxide, which is not listed anywhere I have seen as

been conductive, however this one has quite a complicated structure, so I am

not sure about it.

Tungsten (III) oxide is also known but not formed from this process.

Mix these together and you end up with a greyish white powder which is

partially conductive.

Ian

austesla@exemail.com.au

—–Original Message—–

From: tesla-bounces@pupman.com [mailto:tesla-bounces@pupman.com] On Behalf

Of Phil Tuck

Sent: Sunday, 10 November 2013 3:28 AM

To: tesla@pupman.com

Subject: [TCML] Tungsten Electrode Dust

All,

Does anyone know for fact if the fine white dust that you find around a

rotary spark gap, from the ablation of the electrodes, is actually

conductive? One supposes it is, but logic and reality can be differant.

Regards

Phil T

![]()

Wiring

Wiring is with 4-8 mm automotive cable which gets hot. I was using a large alligator clip to tap the primary and the solder melted. The magnetic steel in the alligator clip was responsible resulting in radio frequency hysteresis losses.