Ionic spinners

2007

Also known as electrostatic corona motors. This is an ionic wind powered

device that makes a small wire device rotate when connected to high voltage.

I will post details of a small one and video soon.

Best results are with DC high voltage. To demonstrate this a 14 foot

(4.2 m) spinner cannot be turned by a Tesla coil making 2 foot sparks (100

kHz AC) but can be turned by a DC supply running perhaps 60kV with 3 inch

sparks.

(click

to enlarge)

(click

to enlarge)

The left photo above shows the 14 foot (4.2 m) arm that turns on a 1

mm shaft and has low enough friction to drift in the wind. The

center photo shows the Tesla coil and the corona from the shaped tip and

multiple breakout points in this 14 second exposure. The Tesla coil

did not move it. The right photo shows the rod electrically

disconnected from the Tesla coil which is off. I have hooked up my 60 kV

supply and on this time exposure of 36 seconds you can see the rod has

rotated through at least 180 degrees (see the faint rod above my head which

is briefly lit by the sparks that I made as it passed).

This lack of performance by a large TC was unexpected. My explanation as to

why a large one doesn't work, but a small one does, is due to the rectifying

effects of different shaped electrodes. Spark length can vary by a

factor of up to three based on my past experiments from a needle point to a

plane depending on which way around the polarity is (negative needle

electrodes give the longest corona). Hence a small streamer from needle points will

ionize a larger volume of air in one polarity than the other due to it's

diode like effect. A mass movement of air can then take place from the

excess of a single charge and thrust occur. With a larger TC, however,

the large streamers can reach a large area well out of the sphere of

influence of needle points and charge accumulation does not occur. To

demonstrate this, your hair does not stand on end if you are near a large TC

but does with much smaller DC voltages.

Now if I had a big diode in line with the corona point then it should work.

500kV high speed diodes however are not cheap. I need to give this more

thought.

Others have run

these on small Tesla coils however.

Lifters

1 2003 (ionic

wind powered device) These are a nifty thing

to do high voltage. In essence they are devices that levitate using ion wind

created from a DC high voltage external source.

(click

to enlarge)

(click

to enlarge)

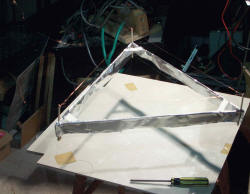

In my Lifter Mk 1 (which is a typical beginners one) a 40 cm triangular ultra light

basla, aluminium foil and wire creation lifts up once around 40kV is

applied. A thin wire supported by balsa wood struts is the source of the

corona and the foil below is attached to the other polarity (positive or

negative). The supply wires are not clearly seen since they get very

agitated with the high voltages. The structure is tethered with cotton

taped to the base. There is occasional arcing across the 3cm between

the top wire and the foil at this voltage. My high voltage source is

the x-ray transformer described below run off a variac. The typical

output used is 30 kV AC which with the addition of a 290 kV diode and

capacitor gives a smoothed, half wave rectified output around 40 kV DC. I have also used

the 100 k ohm resistor

in series to reduce destructive arcing as it burns out the wire.

Lifters 2

2004

(click

to enlarge)

(click

to enlarge)

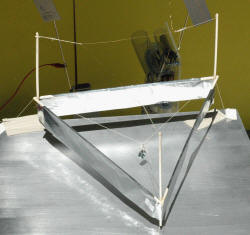

This is Lifter Mk 2 which is a much better flier. Smaller at 6 inches

(15 cm) per side, stronger and a more generous spacing between the foil and

the corona wire. It is powered by a dedicated 30 kV DC stabilized

power supply with one side referenced to earth which means no more sparks

from foil to ground. I use a 100 kohm resistor as above. The

height is limited by the wind outdoors.

(click to enlarge)

(click to enlarge)

Some detail of one vertex of the triangular lifter showing the recession of

the foil and hot glue construction. Note that the upper wire needs to

have the enamel stripped off at least partly but preferably left on the

support wires to the HV source.

The ionic wind is enough to blow out a flame underneath the lifter and can

be felt. This form of propulsion is similar in principle to the ion

engine used to power

Deep Space 1

spacecraft which used on board Xenon. A normal lifter

will not work in a

vacuum. A comparison of the two.

Deep Space 1

Power:

1280 volts, 2500 W from solar cells

Propellant: stored Xenon gas

ionised to Xe +

Speed:

100,000 kph

Thrust:

9 grams (very low but efficient and can go for years)

Cost:

$200 million

Lifter

Power:

30,000 volts, 5 W

Propellant: air ionised to O+,

N+

Speed:

? 5 kph

Thrust:

3 grams (just enough to lift the very light structure)

Cost:

$1000 for full display (actually only $2 for the lifter itself)

This is a

NASA

scientific publication showing no performance in a vacuum and that the

principle of operation is due to air ionisation.

Others have made lifters large enough to have a small payload such as a

mouse.

A

Japanese lifter is 15 ft (5 m) in diameter and is shown lifting to 45 ft

(15 m).

Lifters 3

Aug 2004

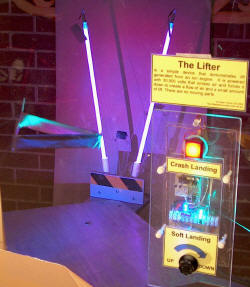

Lifter Mk 3 was developed for a public display. It has custom argon tubes for the upright high

voltage wire supports. In addition it has small neon indicator globes

at the corners of the lifter itself. Very impressive at night. Not

really a high flier however due to the reduced voltage available after the

argons plus the added weight of the small neon tubes. One further

feature is the "Crash land" button. This uses a motorized switch to

short circuit the power supply. This causes a loud and bright spark

visible low down between the upright argons in the left picture, the tall

argons flash and the lifter loses power and falls. Kids (of all ages)

love this one.

(click to enlarge)

I have measurements of the plain vanilla lifter (i.e. no attached neon's)

which is a 30 cm triangle. This jumps up very smartly to its tether

limit at 2 feet.

Input

24 V 0.80 A = 19 W

Output (measured after argons).

no load (argons only but no wires to lifter) ?30 kV 100 uA

plus HV Meter (100 uA FSD movement) 28 kV 130 uA = 3.6

W

plus lifter (no dropping resistor) 22 kV

400 uA = 8.8 W

Threshold for lift is 14 kV.

Hence net current is around 270 uA and net power used by lifter is around 5

W.

The argon tubes drop about 500 V each with the load of the lifter i.e. about

1 kV is lost. (but gain about 50 kV of coolness)

My lifter, give or take, uses 5 W to lift its 3 g (= 0.6 g/W).

This neat little

helicopter weighs about 2500 kG, and lifts a further 2500 kg using 1 MW.

Proportionately 1MW would lift 600 kg with my lifter specs. Only about 1/4

that needed to achieve lift of the helicopter. One wonders if

technology can't offer something more efficient than my triangular lifter

though. I have a few ideas .....

(click to enlarge)

(click to enlarge)

This is the power supply setup using a 30 kV DC regulated supply from a 24 V

transformer and a small PWM (pulse width modulated) controller.

This will be used for the public display lifter soon to be completed.

It does not like repeated short circuits (and tends to blow the 2N3055

drivers) but this has been fixed by using a series resistance (12 kohm 5 W

plus 15 kohm 5 W in series). This weakens the "Crash landing" spark

which then had to be boosted with a 570 pF 40 kV doorknob capacitor.

(click to enlarge)

(click to enlarge)

The left photo above is a sunset shot and the right photo shows a view between the

argon tubes. I have highlighted the lifter separately. With this shot you

can see the range of vibration of the first order harmonic of the closest

wire which is about 1 inch in amplitude. If the tension is a little higher or humidity a

bit less, this changes to a second order harmonic with a node in the

middle. I guess this would be preferred as excursion is less, however the

lift will be more as the wire gets closer and if there is an inverse square

law then it may even be helpful.

My balsa supports started to track sparks and carbonize as the humidity

picked up this evening. This is a prelude to a crash and burn. In

desperation I used a light oil spray on the balsa supporting the upper wire

which seems to have worked fine.

(click to enlarge)

(click to enlarge)

This shows the transparent control panel exposing the electronics of the PWM.

The two controls are a red "Crash landing" control and a rotary "Soft

landing" control. The right picture shows the lifter in the acrylic display during testing.

I am concerned by the radio frequency interference on both AM (~1 Mhz) and FM

(~100 Mhz).

There is no problem open circuit and the DC HV wire is shielded up to the

upright argon tubes which serve as supports for the HV wire. Shorting the

argon tubes does not seem to make a difference. I have tried a ferrite cored

coil in series with the active lead with and without a resistor (330 K)

although the latter does decrease performance. The sealed 30 kV HV unit

is driven by a switch mode supply. This supply is giving minimal RF

interference as a whine which I think I have fixed by putting a suppression

circuit in the 24 VDC line. Some of the RF was corrected with a better

connection to the 2x2 ft ground plane. Unfortunately correcting the RF

at its presumed source, the corona from the upper wires, is not feasible due

to weight constraints.

I recently had to display the lifter within a few feet of a large plasma

display monitor fortunately without problems. Interestingly, in the

final version of the lifter, I did not remove the enamel from the support

wires which means that they are a lot less agitated and give a lot less RF

interference. I have also wound the support wires into a loosely

spaced coil of about 10 turns around the last 6 inches of the argons to try

to help block RF but I am uncertain if it helps.

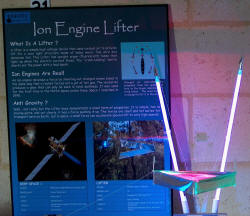

The lifter has now (Nov 5th 2004) been installed at the

Gravity Discovery

Centre in a 1.5 m square acrylic enclosure. This is the public interface

to the gravity wave detector under development here in Western Australia.

Still running in May 2006 with periodic replacements of the lifter and

repair of fractured and oxidized wires.

(click to enlarge)

(click to enlarge)

The left picture shows the display poster. The right picture shows the

full installation running. It has to

be public proof and withstand lots of 'crash landings' from about 18 inches.

The balsa frame is hot glued and also has some reinforcement at the point of

impact. The support cotton threads have been upgraded to string

from a small kite which is light and very strong. The display is lit

by small arrays of lights with 8 high intensity LED's each with green, blue

and purple coming from different directions. The "soft landing" switch

controls the power to the HV supply and is spring loaded to return to the up

position. It is a challenge to get a truly soft landing and is nicely

interactive in this way.

(click to enlarge)

(click to enlarge)

A demonstration by the lovely Sylvia from the GDS who is practicing her

controlled flying.

(click to enlarge)

(click to enlarge)

Above shows some design modifications in response to problems developing

during the first 12 months it has been on display. Wire fracturing was a frequent

problem as the wires are vibrating for 8 hours per day. I have now used some

fine Litz wire which has 7 strands plus a strengthening fiber and is really

strong and should be much more resistant to fatigue fracture. (donated by

Bert Poole)

The other problem I have with long term lifters is HV creep and charring of

the balsa supports. I hope to deal with this with the nylon line support

shown above that gives about 1 inch extra distance of the wire to the Balsa

upright with a mild penalty in geometry as the top wire is now not

vertically above the aluminium skirt.

Lifters 4 80 kV

Nov 2005

Well, here is my HV lifter running from my 80 kV voltage multiplier driven by

a flyback and ZVS driver. It sparks at about 4 1/2 inches between the wires

and skirt when turned up full.

(click to enlarge)

(click to enlarge)

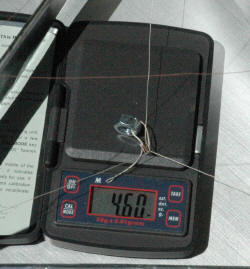

It has a LOT more lifting power and is shown here lifting 4.60 g while the

lifter weighs 4.13 g. In other words it is lifting more than it's own weight.

(click to enlarge)

(click to enlarge)

I did try dual corona wires but there was no additional benefit with this

setup. Either the extra weight penalty or load on the power supply

might have caused this result. I later removed it.

(click to enlarge)

(click to enlarge)

These are time exposure shots showing corona off the lifter with a few 4

1/2 inch sparks thrown in for good measure. Note the lead in wires. I have

kept the lifter on the base to avoid movement. At least the threads that

support the wires prevent arcing down the balsa supports. Left photo

exposure is 58 seconds and the right photo is 22 seconds.