My earliest can crusher. Can crushing is a sudden constriction of a can using very high induced current.

“Continue reading” for more details and photos.

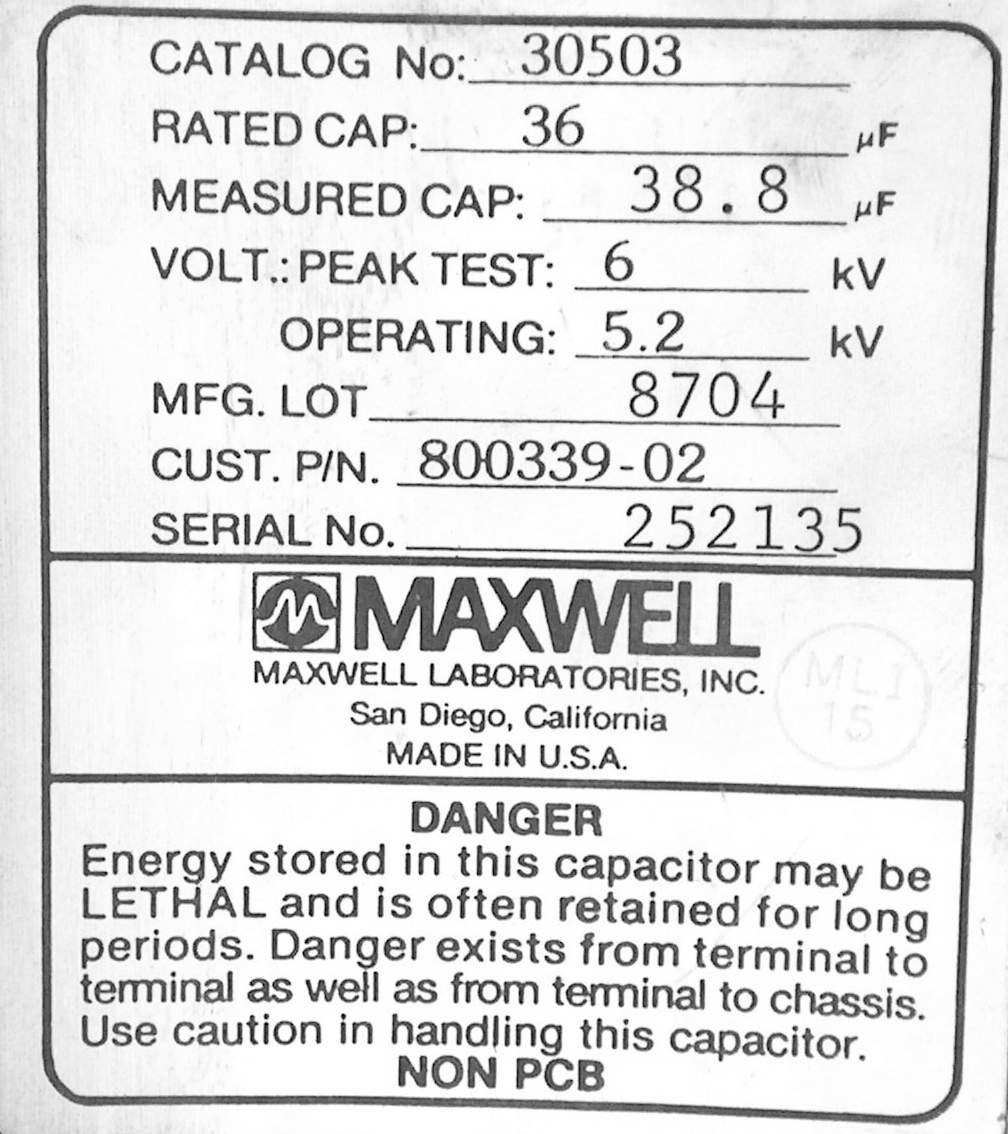

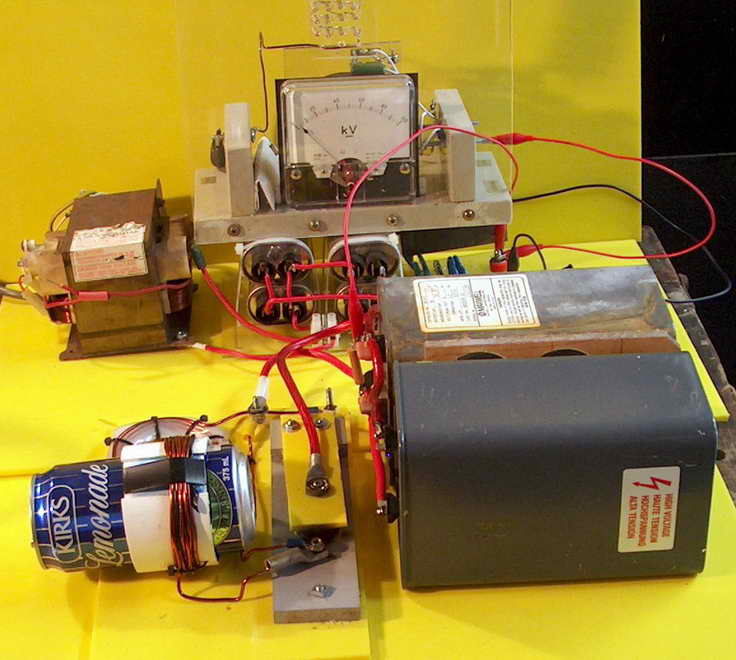

This is done by discharging a capacitor through a coil wrapped around the aluminium drink can. The high voltage pulse capacitor is necessary to generate very high peak currents to induce currents in the can which magnetically heat and crush it. Both capacitors in this early setup come from old style monophasic medical defibrillators. These normally deliver up to 360 joules into the chest body resistance between large conductive pads of around 50 – 100 ohms (the machines print this out with each shock). There is a series coil of around 47 mH to limit peak current flow in the medical situation. Both capacitors are Maxwell pulse rated around 36 uF at 5.2 kV and each stores 500 J (total 1000 joules). I charge it with the supply I made for HeNe lasers.

One of my early can crusher setups made from 8 turns of 2 mm wire. My later can crushers only use a few turns. I have not tried this before as I believed that I did not have enough power to crush a can. Interestingly my 800 V supply using electrolytic capacitors with SCR switching barely makes a dent in the can although the delivered energy of 1500 joules is greater. A rapid rise time is important and the 1 ms rise using electrolytics is far too slow by a factor of 10.

One of my early can crusher setups made from 8 turns of 2 mm wire. My later can crushers only use a few turns. I have not tried this before as I believed that I did not have enough power to crush a can. Interestingly my 800 V supply using electrolytic capacitors with SCR switching barely makes a dent in the can although the delivered energy of 1500 joules is greater. A rapid rise time is important and the 1 ms rise using electrolytics is far too slow by a factor of 10.

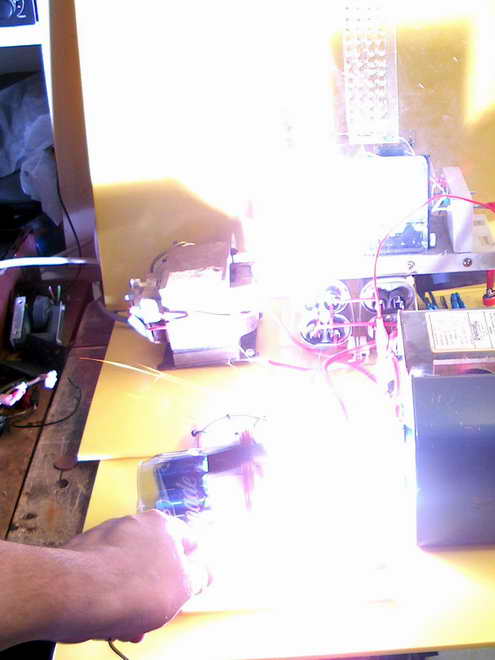

The right photo above shows the flash when it fires.

The right photo above shows the flash when it fires.

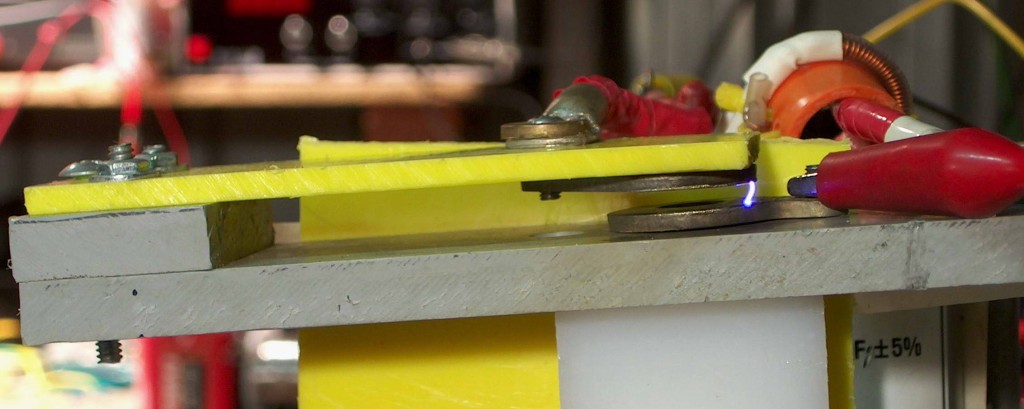

The momentary trigger switch (the grey and yellow plastic device above) with large metal contacts. I have added a 2 kV low intensity arc to show the contact points. Not really cool like a triggered spark gap. On one occasion the can shorted the coil and I could feel the blast wave from the spark. I wear hearing and eye protection and look away (while firing and taking the picture)!

The momentary trigger switch (the grey and yellow plastic device above) with large metal contacts. I have added a 2 kV low intensity arc to show the contact points. Not really cool like a triggered spark gap. On one occasion the can shorted the coil and I could feel the blast wave from the spark. I wear hearing and eye protection and look away (while firing and taking the picture)!

Related pages

Try something else

External links

Photo Date: Dec 12, 2003

Can crushing

Can crushing Comet McNaught

Comet McNaught