It is of interest to know the current induced in a can at the time of can crushing. This can be done by direct measurement of current with a Rogowski coil or by measuring voltage drop in the can.

It is of interest to know the current induced in a can at the time of can crushing. This can be done by direct measurement of current with a Rogowski coil or by measuring voltage drop in the can.

“Continue reading” for more details and photos.

Method 1: Direct measurement of current with a Rogowski coil

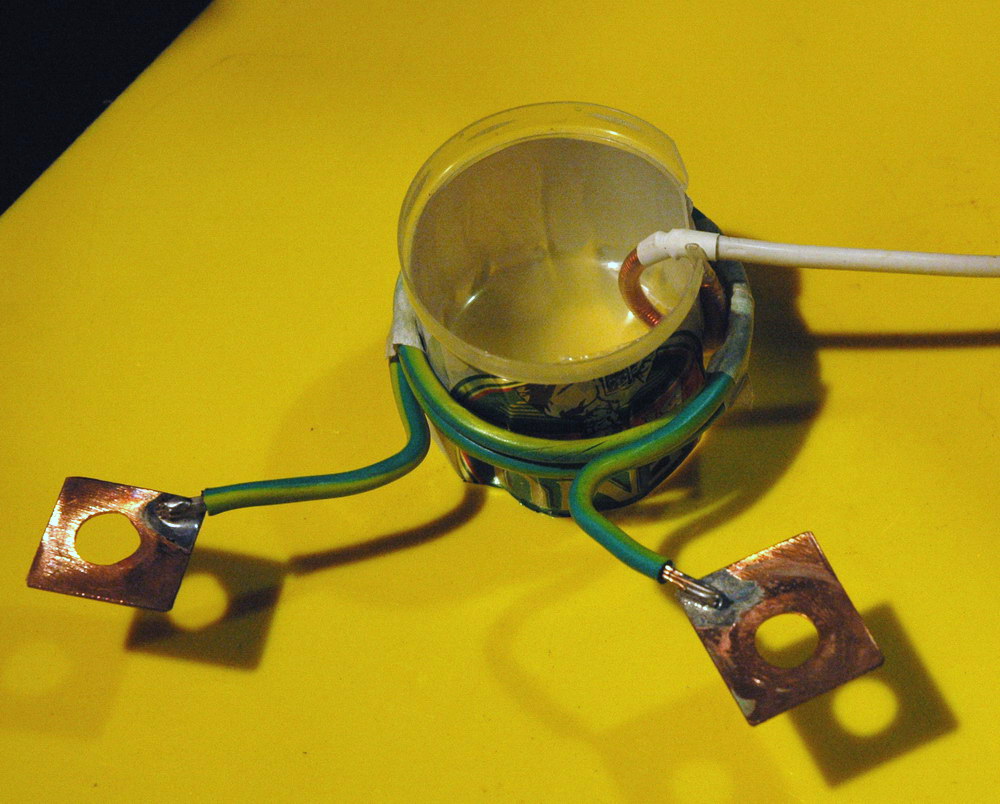

Above is a 2 inch can section braced with plastic to prevent crushing and the Rogowski coil was placed around the section to measure current.

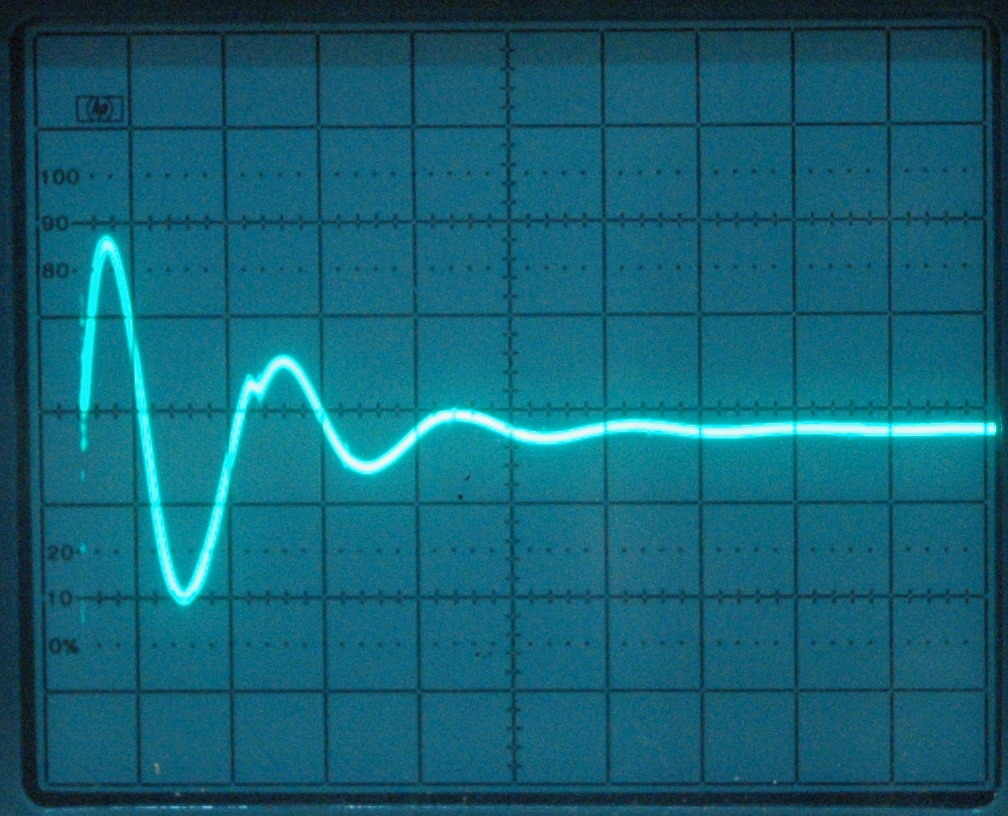

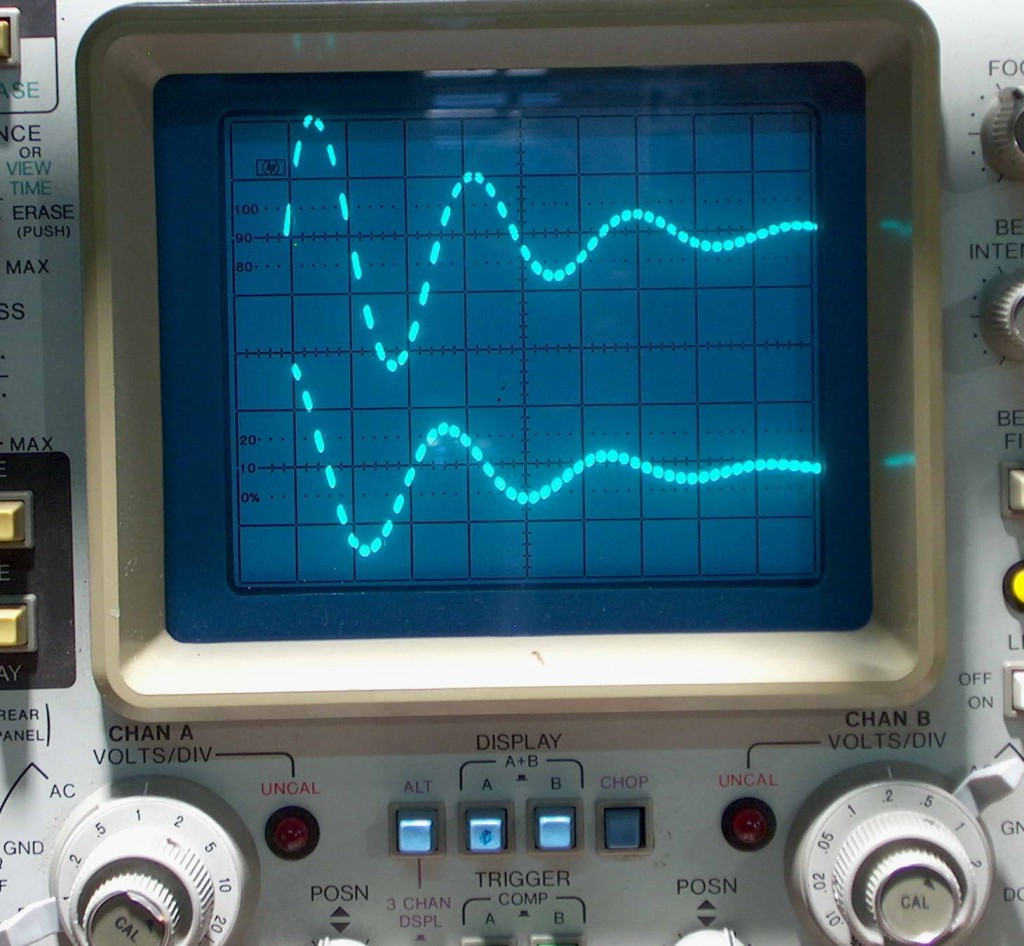

The can current scale is 5000 A/div vertical and 50 us/div horizontal. At 2 divisions from baseline this gives 10,000 A peak flowing within the can in a 50 usec pulse.

The can current scale is 5000 A/div vertical and 50 us/div horizontal. At 2 divisions from baseline this gives 10,000 A peak flowing within the can in a 50 usec pulse.

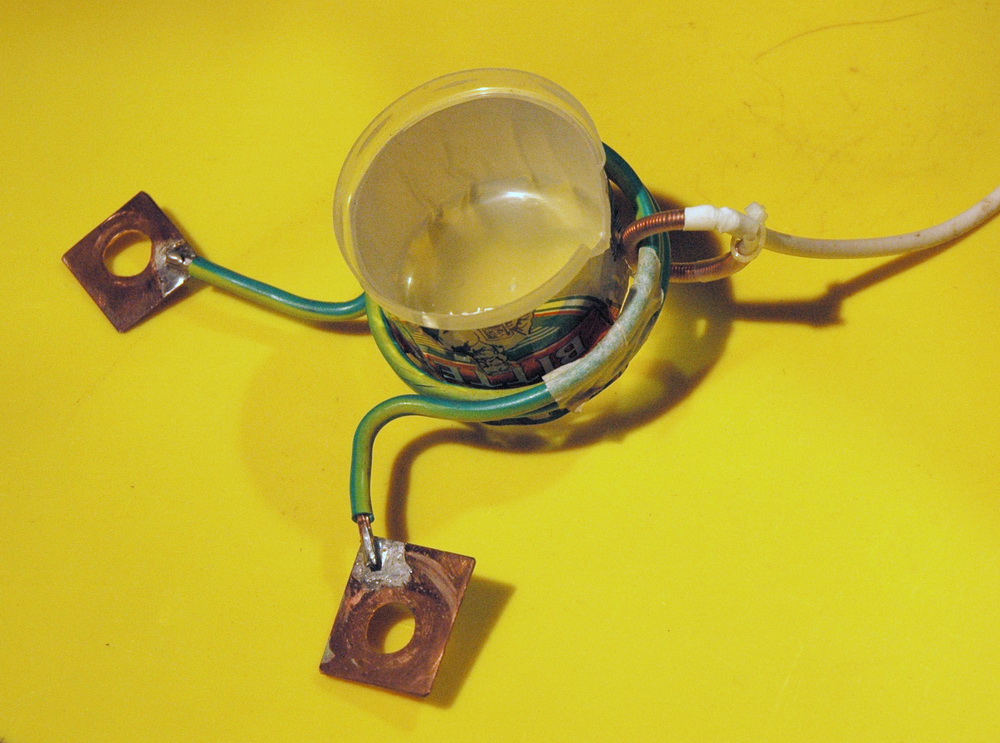

So now look at the current within the crushing coil rather than the can itself. Note the positioning of the Rogowski coil.

The Rogowski coil is around the 3 turns of the crushing coil.

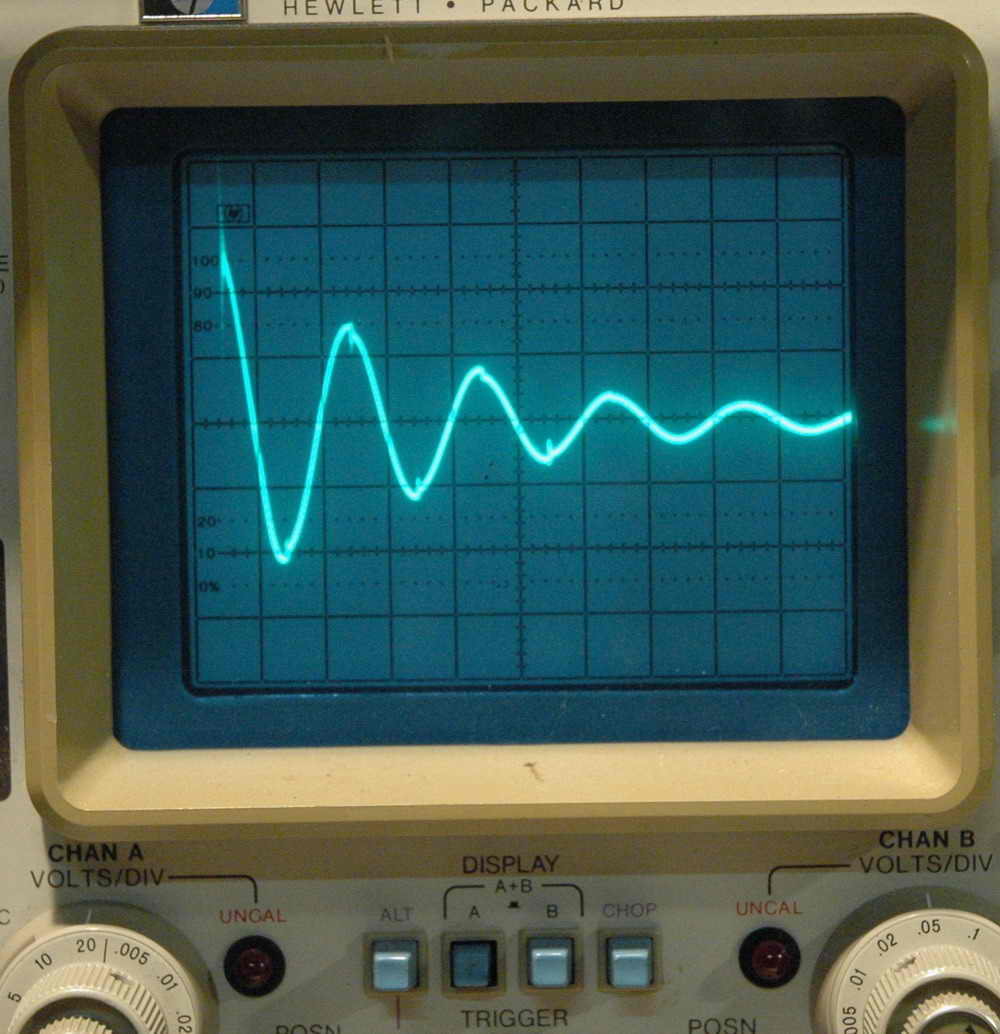

This shows the coil current of the 3 turns together. Scale is 5000 A/div vertical and 50 us/div horizontal. Hence a peak of 3.4 divisions above the baseline gives a measurement of current in 3 turns of 17,000 A which is a 5600 A per turn.

This shows the coil current of the 3 turns together. Scale is 5000 A/div vertical and 50 us/div horizontal. Hence a peak of 3.4 divisions above the baseline gives a measurement of current in 3 turns of 17,000 A which is a 5600 A per turn.

Each of the 3 turns of 5600 A induces one third of the can current of 10,000 A. Therefore 1 turn induces 1/3 of 10000/5600 of its current to the can.

“Each turn delivers 60% of its current to the can”

Perhaps not super efficient as far as transformers go but interesting nevertheless.

Since the can and 1 turn have a similar diameter and hence inductance then around 60% of power is transferred as well.

The set-up used was:

Capacitor (C) = 215 uF

Voltage (V) = 1000 V

Energy =1/2 C*V*V = 110 J

110 Joules is small but can still dent the can section. The capacitor bank can deliver 100 times this power.

Note that this is a bit artificial in that the can does not crush. There may also be inaccuracies with the Rogowski being in close contact with the crushing coil. With a perfectly constructed Rogowski coil this should not matter however.

Method 2: Direct measurement of voltage within the can.

Another method to measure coil current is to measure the voltage generated in the can. Simply measuring the voltage across the cans with contacts made at opposite points will enable the current to be calculated. This is not simply Ohm’s Law however as the pulse means that the inductance will also contribute.

The CRO shows a 60 V peak across the diameter of the can when driven with the same voltage and energy above. The vertical scale is 20 V/div and the horizontal 50 us/div.

The DC resistivity of aluminium is 2.6 10-8 ohm meters.

Resistivity = Resistance (ohms) * area (m2) / length (m)

The dimensions of the can segment are 0.18 m long (=circumference), 0.06 m wide and 0.0001 m thick. Hence the resistance is around 0.78 milliohm. Using Ohm’s Law alone with 60 V would give a current of 660 kA which is not likely so it indicates that inductance of the 1 turn (of about 0.1 uH) is significant. Skin depth at 10 kHz is about 1 mm so is much greater than the thickness of the can by a factor of 10.

Impedance Z (Ohms) = 2 * pi * F (freq in Hertz) * L (inductance in Henries)

= 6 milliohms

Using this impedance and the 60 V i = V/Z

Hence current in can = 60 /.006 = 10 kA which fits surprisingly well with the Rogowski coil measurements.

Related pages

Measurement of high current pulses

Measurement of high current pulses

Try something else

External links

Photo Date: April 11, 2005

Magazines

Magazines