My first (unsuccessful) attempt at a transverse excited atmospheric pressure (TEA) nitrogen laser and why it didn’t work.

“Continue reading” for more details and photos.

This is a free air laser with no mirrors that gives an ultra short ultraviolet pulse. Typically at atmospheric pressure in air (78% nitrogen) the laser pulse discharge is only about 1 nS and occurs at 337.1 nm. This means that the light pulse is only 1 foot (30 cm) long. After this there are more nitrogen molecules in the lower than the higher energy state and lasing ceases. The lower level lasts very much longer before lasing can take place again. These ultra short discharges mean that they are extremely sensitive to any inductance in the path.

The graphic gives a sort of idea of what is happening in a superradiant laser (ie light has only one pass with no mirrors) and has a beam from both ends.

The power in each pulse however is typically 155 uJ measured on one experimenter’s power meter on his similar laser. At 1 pulse per sec this means that each pulse delivers a peak power of 155 kW during the nanosecond that it is on. At 6 pulses per second this is 1 megawatt peak power (sort of) and average power of 1 mW which is the same as a handheld diode laser.

Lower pressure and pure nitrogen lasers are much less critical with discharges of typically 20 nS.

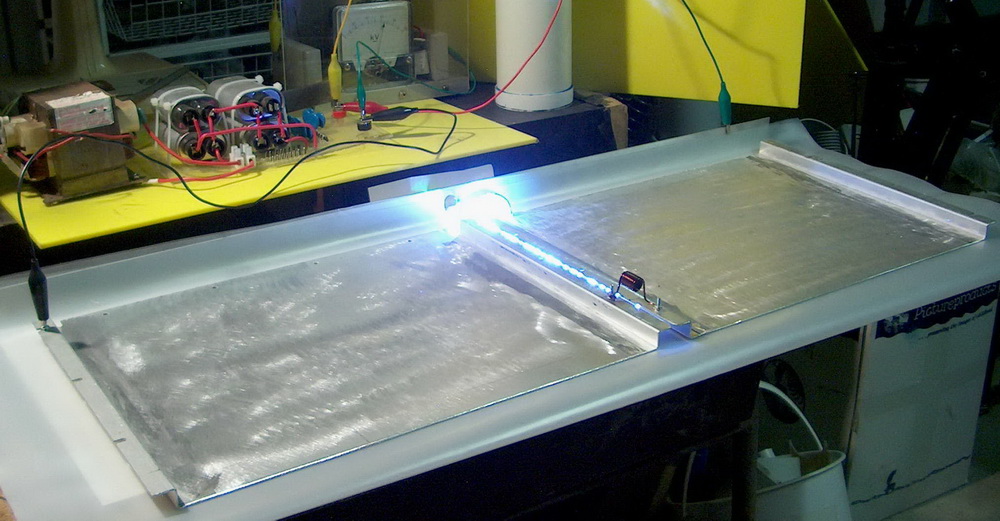

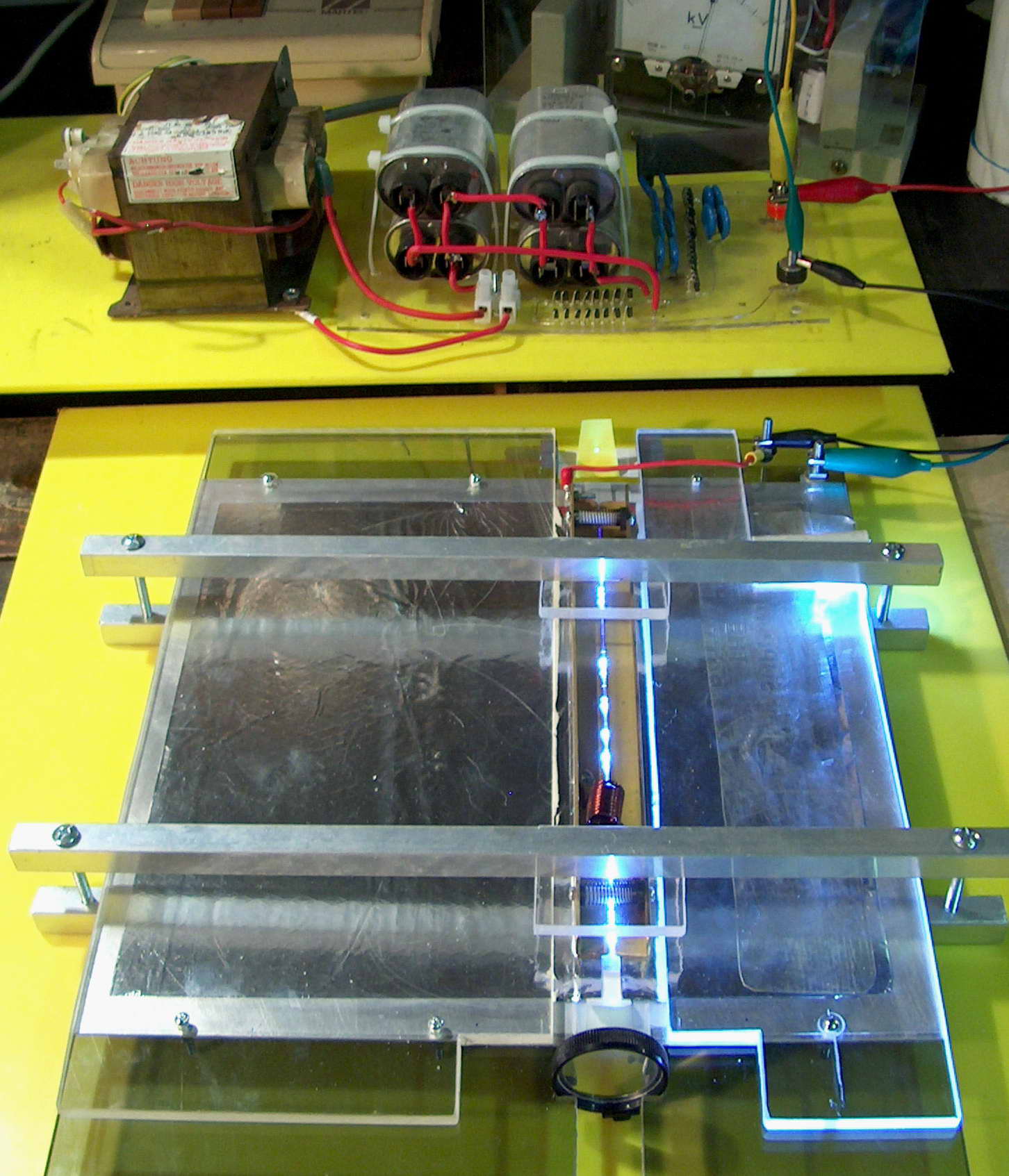

So on to Nitrogen laser 1. This home baked item was made from 3 aluminium sheets. A bottom full sized one and a split upper one with a spark gap between. The gap is about 1 mm and the two upper sheets are joined by a 10 turn inductor. One of the upper plates is discharged to the lower plate with a separate spark gap. It is all run from about 9 kV. The capacitance of the combined upper plates with the lower plates is 4 nF. The upper sheets measure about 16 x 20 inches (40 x 50 cm).

The main gap is shown firing and the paper coloured with a fluorescent marker is shown at the top of the picture lighting up but not lasing.

I subsequently learnt that Nitrogen Laser 1 would not work for several reasons.

Firstly, I was putting too much voltage and power into it. The spark gap repetition rate is in the upper audio range and it really squeals in action. The optimum for N2 lasing is much lower and often less than 25 Hz.

Secondly, the effective 1/4 turn of the stepped up rails was probably significant factor at reducing the discharge rate and has far too much inductance for nanosecond speed discharges.

Thirdly, I needed to use a much thinner dielectric and a lower voltage. I was using up to 4 layers of 8 mil (0.2 mm) polyethylene groundsheet to standoff the voltages of up to 30 kv that I was using.

Related pages

Try something else

External links

Photo Date: May 23, 2004

Nitrogen Laser 2

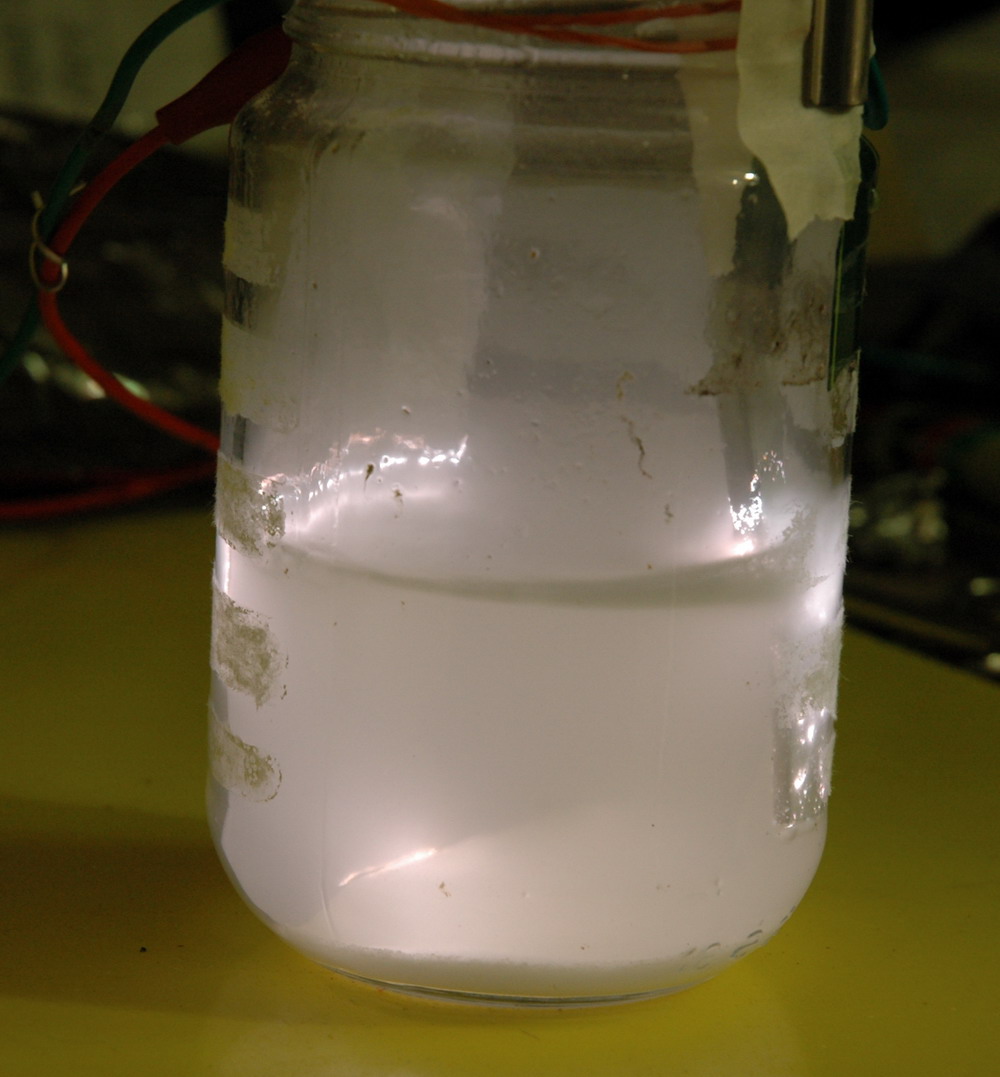

Nitrogen Laser 2 Electrolytic capacitor

Electrolytic capacitor