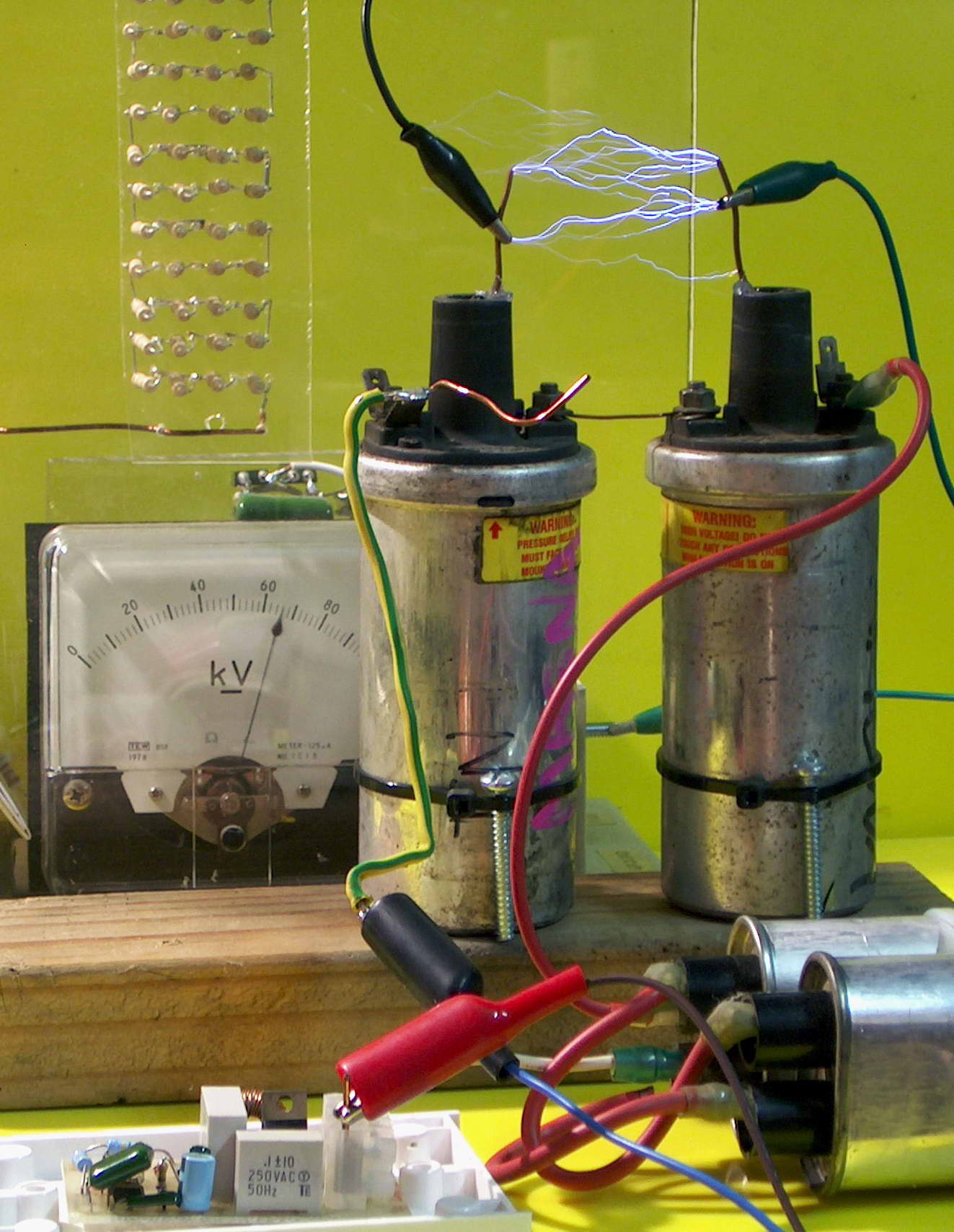

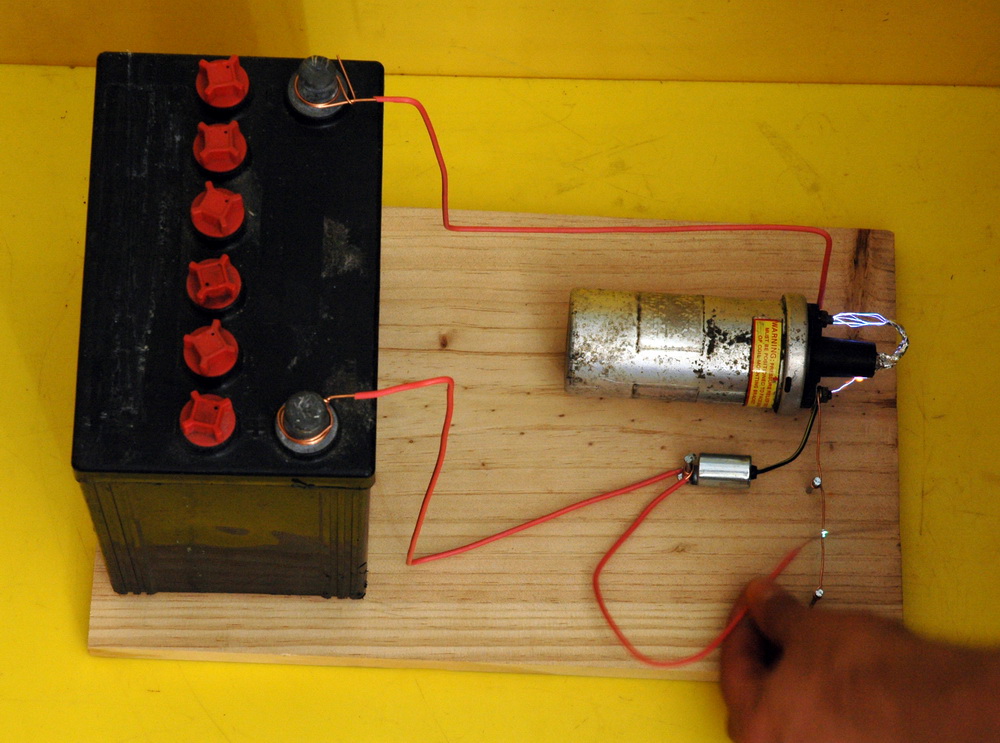

Car ignition coils make great spark sources. After all they were designed to power a spark plug. Now, put two of them out of phase and the sparks are doubled in size. Here are some examples.

Car ignition coils make great spark sources. After all they were designed to power a spark plug. Now, put two of them out of phase and the sparks are doubled in size. Here are some examples.

“Continue reading” for more details and photos.

Ignition coils driven by SIDAC’s discharging a MOT capacitor supply

This is for the photo above. For more abuse of ignition coils than a 12 V battery can deliver, one can drive them at a higher voltage – like 2000 V. This very simple circuit uses the transformer, capacitor and diode out of a microwave oven (MO) to supply 2000 VDC. Once the voltage rises to 2000 V some silicon switches called SIDAC’s (silicon diode for alternating current) fire, dumping the energy into two ignition coils to give sparks of easily 5 cm. I am using 9 SIDAC’s in series each rated at 240 V 1 A RMS and 20 A pulse. Each is shunted with a 1 Mohm resistor to give more even voltage division. There is a 10 Kohm 10 W resistor used for these shots but power draw is triggering a 10 A cut-out and there is sufficient heating of resistor, diode and SIDAC’s to only allow short runs. 50 Kohm will allow about 4 sparks per second.

Unfortunately this is very hard on the ignition coil’s insulation. I have lost one coil but the remaining one still puts out 3 inches and also about 10 inches of surface tracking (below).

![]() This is a really interesting photo. It demonstrates that a spark will go 3 times further along a surface than through the air even when dry and clean. This is why high voltage insulators such as used on power lines are corrugated to prevent surface tracking.

This is a really interesting photo. It demonstrates that a spark will go 3 times further along a surface than through the air even when dry and clean. This is why high voltage insulators such as used on power lines are corrugated to prevent surface tracking.

Ignition coils driven by a light dimmer

A simple way to drive two ignition coils is with a light dimmer in series with the 250 VAC mains and a capacitor of perhaps 1 – 10 uF. I used two microwave oven caps in parallel for about 2 uF at 2000 V which gave sparks of about 2 inches (5 cm). Light dimmers are 2 wire devices that can be inserted any way around.

My meter says about 60 kV peak but may be over reading a bit.

My meter says about 60 kV peak but may be over reading a bit.

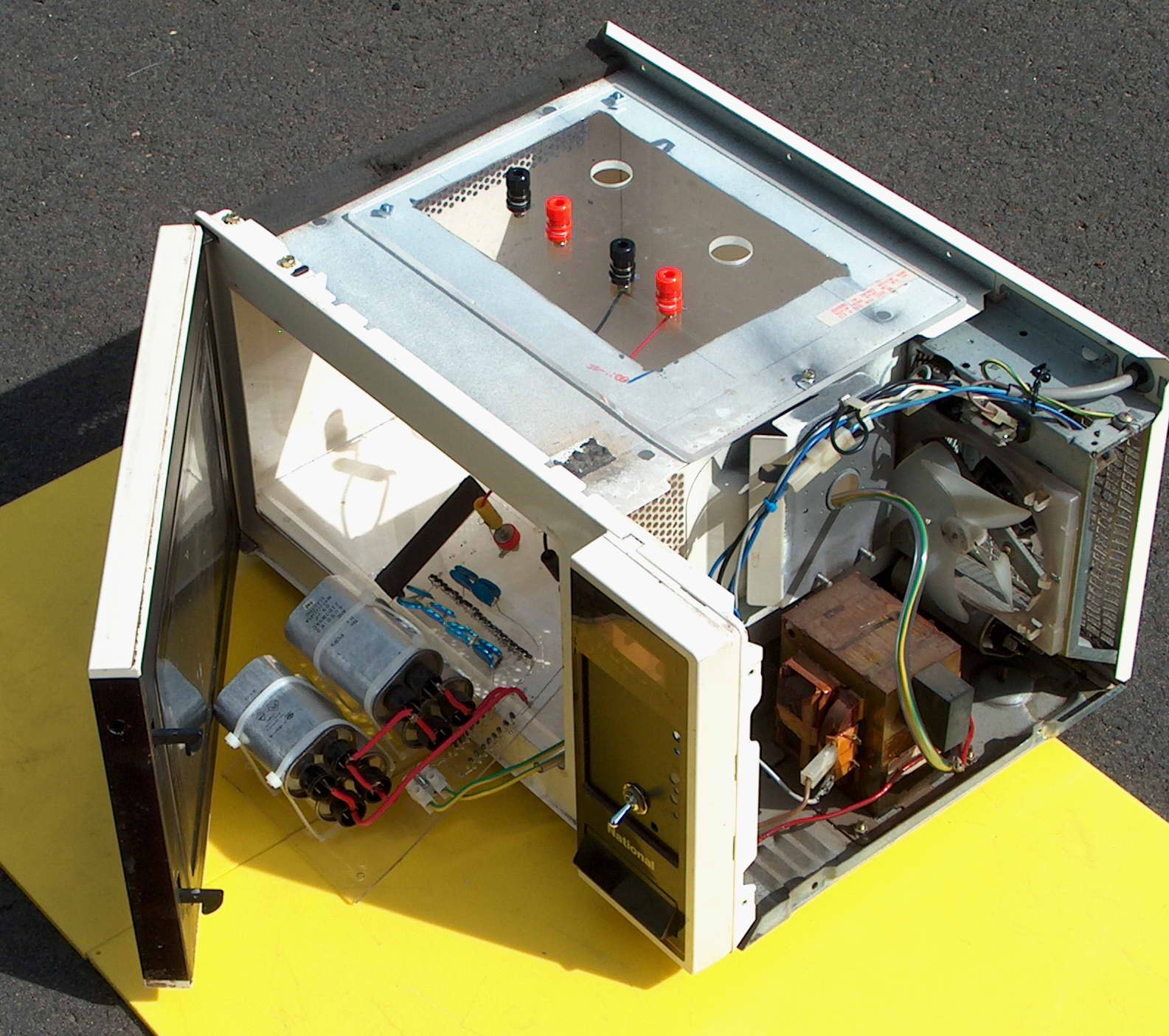

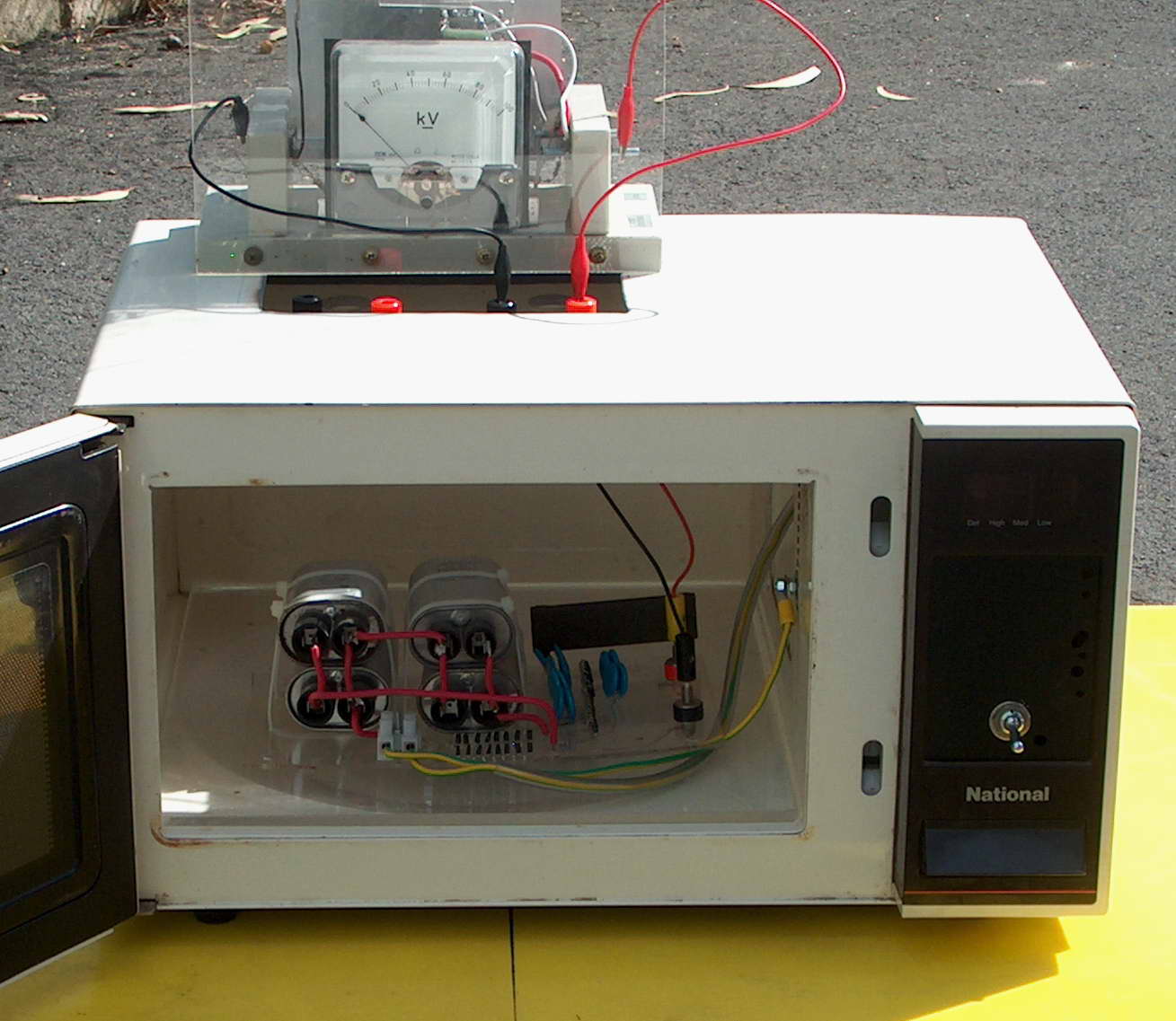

Ignition coils driven by SIDAC’s in a microwave oven

This supply is built into a microwave oven, keeping a lot of the useful components and providing a large safe container. And they are free!

I use my MOT (Microwave oven transformer) multiplier originally constructed as a HeNe laser supply which gives about 9 kV firing and 2 kV running, ballasted by 30 kohms. I have never had any problems with this supply which gets used for all sorts of general HV stuff in the range 1 – 9 kV such as nitrogen lasers.

To accommodate these projects, so that they look less out of place in a modern kitchen, I rewired a microwave oven, keeping the existing safety interlock, light, fan and transformer. I removed the magnetron and old electronics and wiring. I then cut a hole in the cooking cavity and outer case with an angle grinder, added terminals and presto, a neat HV supply. The HV lead from the transformer passes through the microwave waveguide to the cooking cavity with the wire in plastic tubing for extra insulation. The fan helps cool things and the safety interlock turns off the power when the door is open. (I forgot about this and thought I had blown a fuse).

I can access the HV output from the ignition coils for 60 kV and also the multiplier directly for 9 kV.

In good Tesladownunder tradition, total cost is almost nothing, being made almost entirely from scrap microwave ovens, old ignition coils and only a handful of new parts such as the SIDAC’s.

Related pages

Try something else

External links

Photo Date: 2004

Beginners sparks

Beginners sparks